Electric bicycles are a type of vehicle that uses electricity as an auxiliary energy source, with a variety of classifications and structural features. Here is an overview of the types, structure, assembly production process, and automated production line equipment of electric bicycles:

Types of Electric Bicycles

Electric bicycles come in a wide array of types, which can be categorized based on various criteria. For instance, based on the number of wheels and structural types, they can be classified into electric bicycles, electric motorcycles, electric unicycles, electric four-wheelers, etc. Additionally, they can be categorized based on power sources, methods of electricity provision, driving methods, appearance, purpose, and more.

Structure of Electric Bicycles

The basic structure of an electric bicycle typically includes five main components: the frame, electric drive device (motor), rechargeable battery, charger, and control system. The frame is generally similar to that of a bicycle and has the function of manual riding. The electric drive devices mainly include friction drive, central shaft drive, and electric hub drive, among others. Battery types include lead-acid, nickel-cadmium, nickel-metal hydride, and lithium-ion batteries. Chargers are usually designed with automatic conversion of constant current, constant voltage, and float charging stages to extend battery life. The control system has multiple protective functions, such as power display, wireless speed adjustment, soft start, etc.

Assembly Production Process

The assembly production process of electric bicycles involves several steps, including raw material processing, frame welding, assembly of core components (such as batteries, motors, controllers), wheel assembly, circuit connection, and exterior painting. This process requires precise arrangement of procedures to ensure production efficiency and product quality.

Automated Production Line Equipment

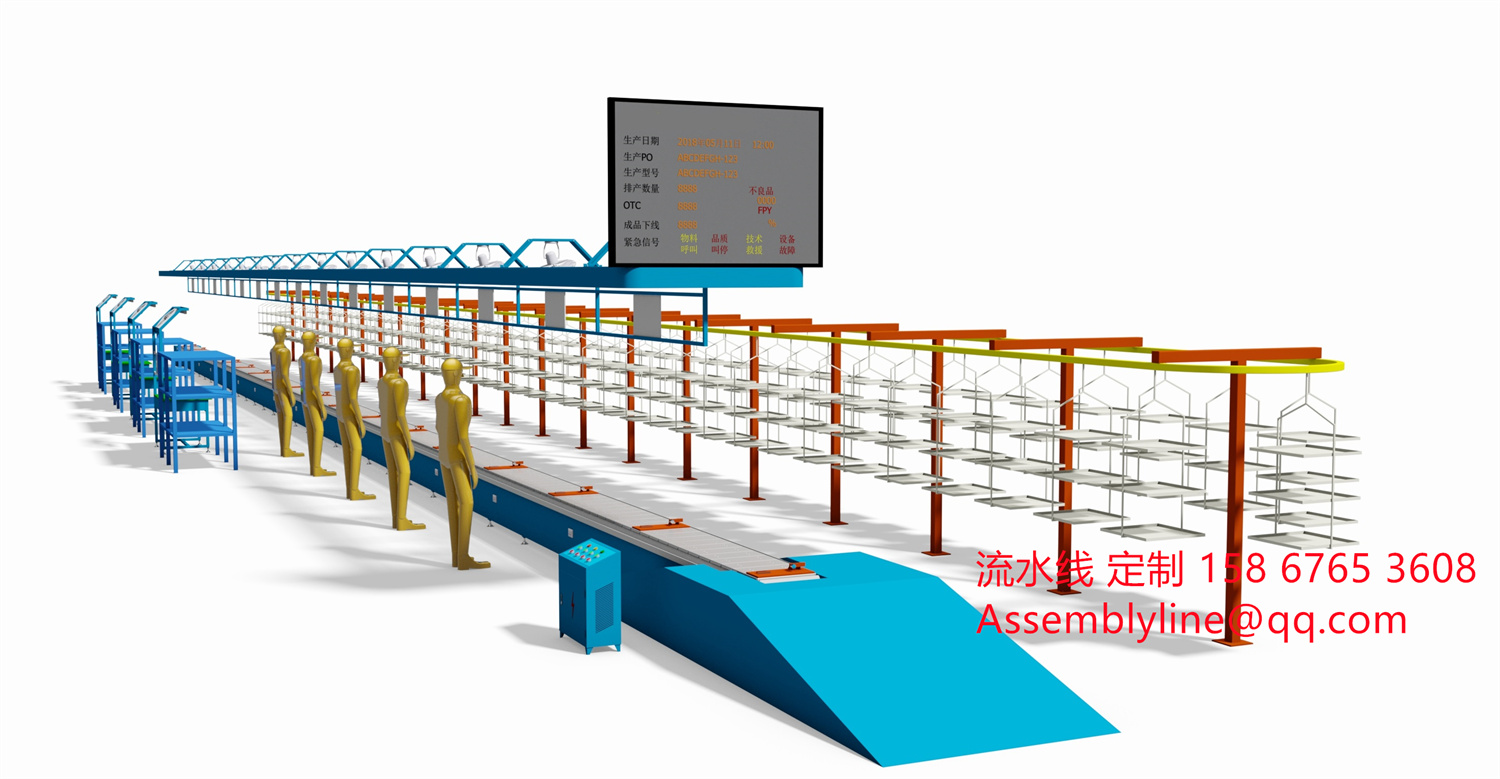

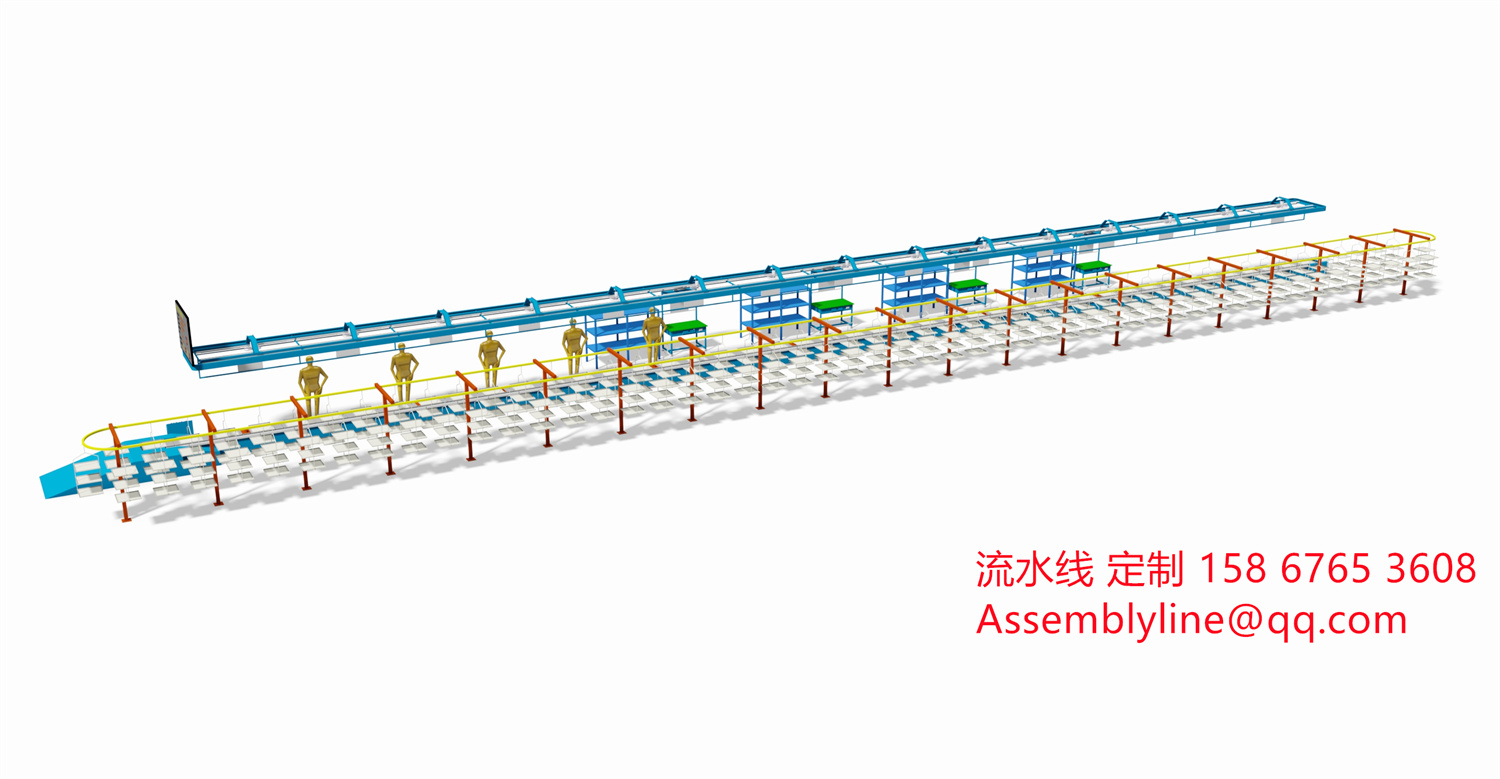

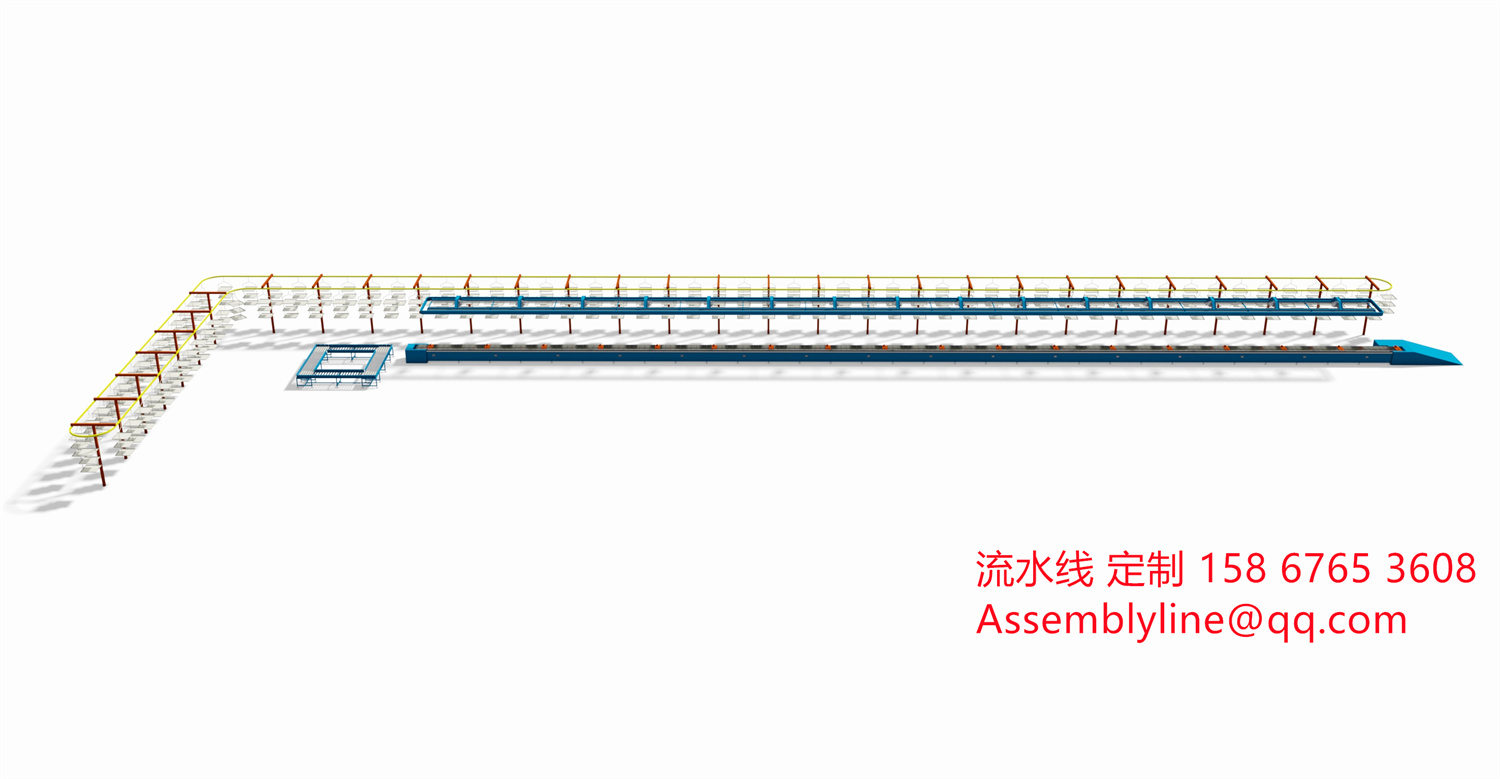

With the advancement of technology, the assembly of electric bicycles increasingly utilizes automated production line equipment. Automated production lines can include a frame skeleton upside-down assembly line and a body parts upright assembly line, allowing for the installation of key components with the frame inverted, reducing the impact of the frame on component installation, reducing operator fatigue, and ensuring installation efficiency and quality. The design of the production line usually takes into account ergonomics, using circular and multi-level designs to enhance process flexibility and operator comfort, while saving production space.

Automated production lines also include electric torque tools, display devices, etc., for displaying production instructions and error prevention measures, preventing component omissions, and ensuring assembly quality. In addition, the transmission mode of the production line can be flexibly adjusted to meet the needs of different production efficiencies.

Through these automated and semi-automated production line equipment, the assembly process of electric bicycles is more efficient and standardized, which helps to improve the performance and consistency of the final products.

The electric bicycle assembly line is an automated production system designed for the efficient manufacturing of e-bikes. It integrates key components such as frames, motors, batteries, and control systems through a sequence of precisely arranged processes. The structure of an electric bicycle typically consists of five main parts: the frame, electric motor, rechargeable battery, charger, and control system. The assembly process involves meticulous steps starting from raw material processing to final assembly, including frame welding, component installation, circuit connections, and quality checks, ensuring each e-bike meets performance and safety standards.

Electric bicycle Assembly line Production line

Factory address: East Industrial Cluster, Wenling City, Zhejiang Province

Aircraft: Taizhou Luqiao Airport (1 hour) Wenzhou Airport (2 hours)

High speed rail: Wenling Station (40 minutes)

Expressway intersection: Wenling North (15 minutes) Wenling East (20 minutes)

Contact our engineering team and get company info

Email: Assemblyline@qq.com