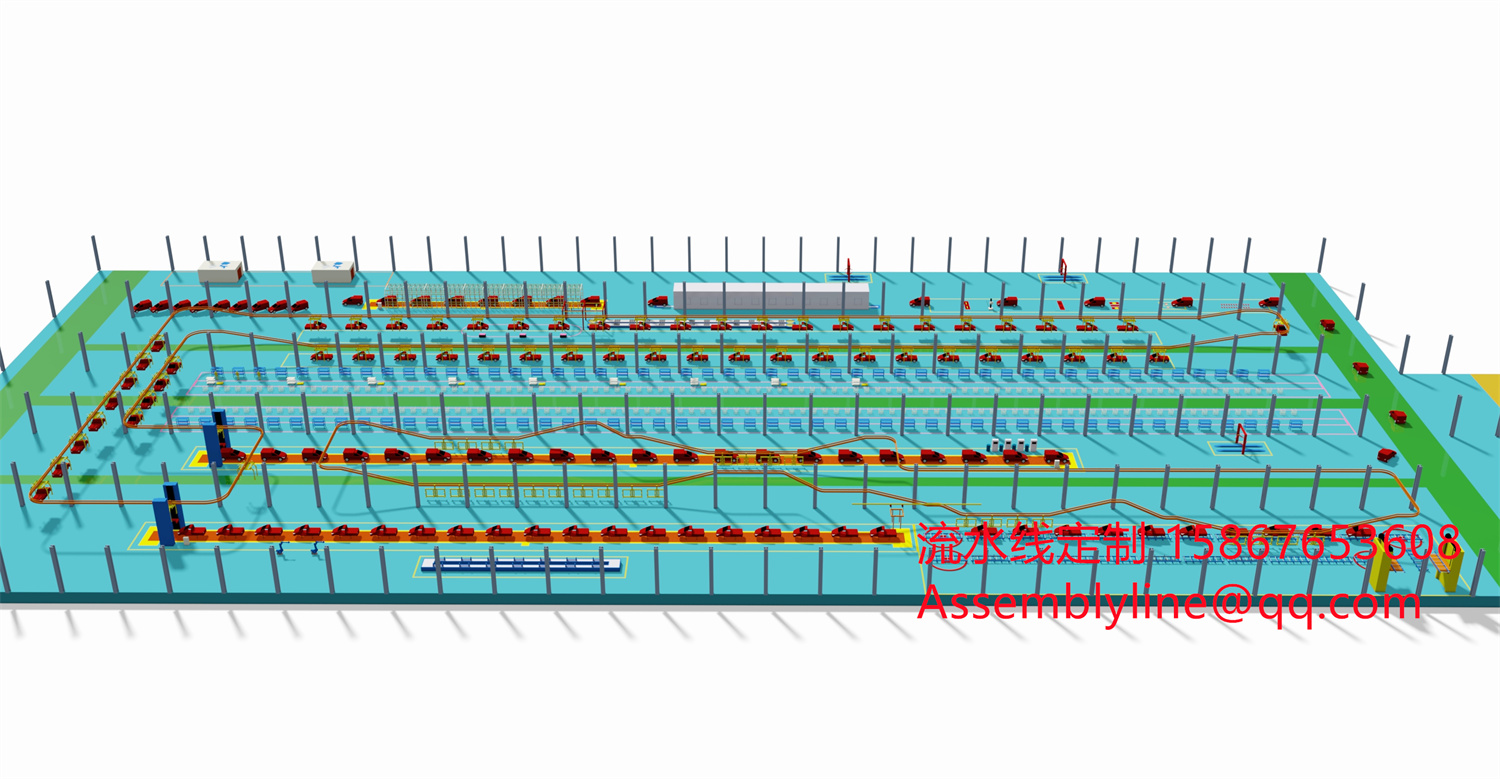

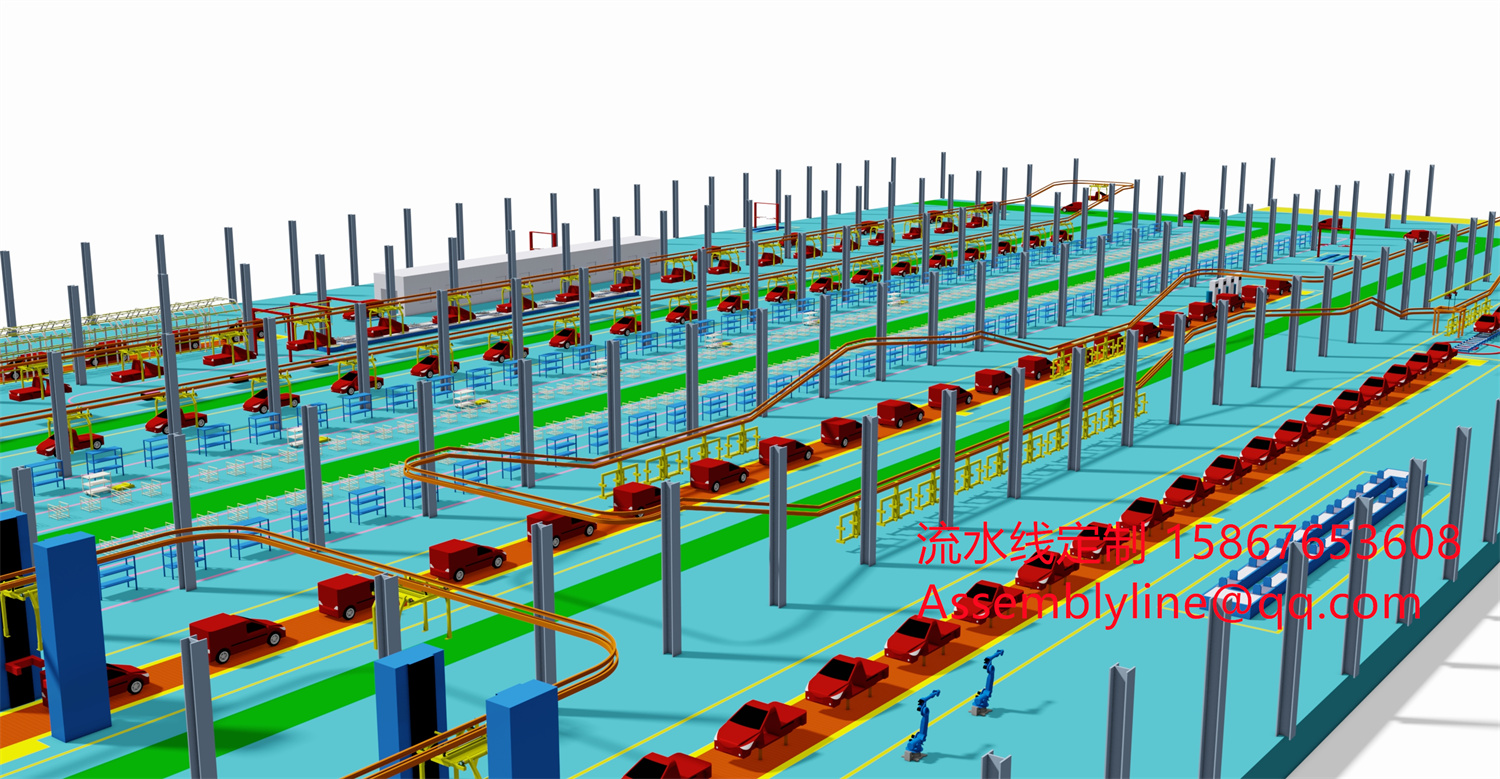

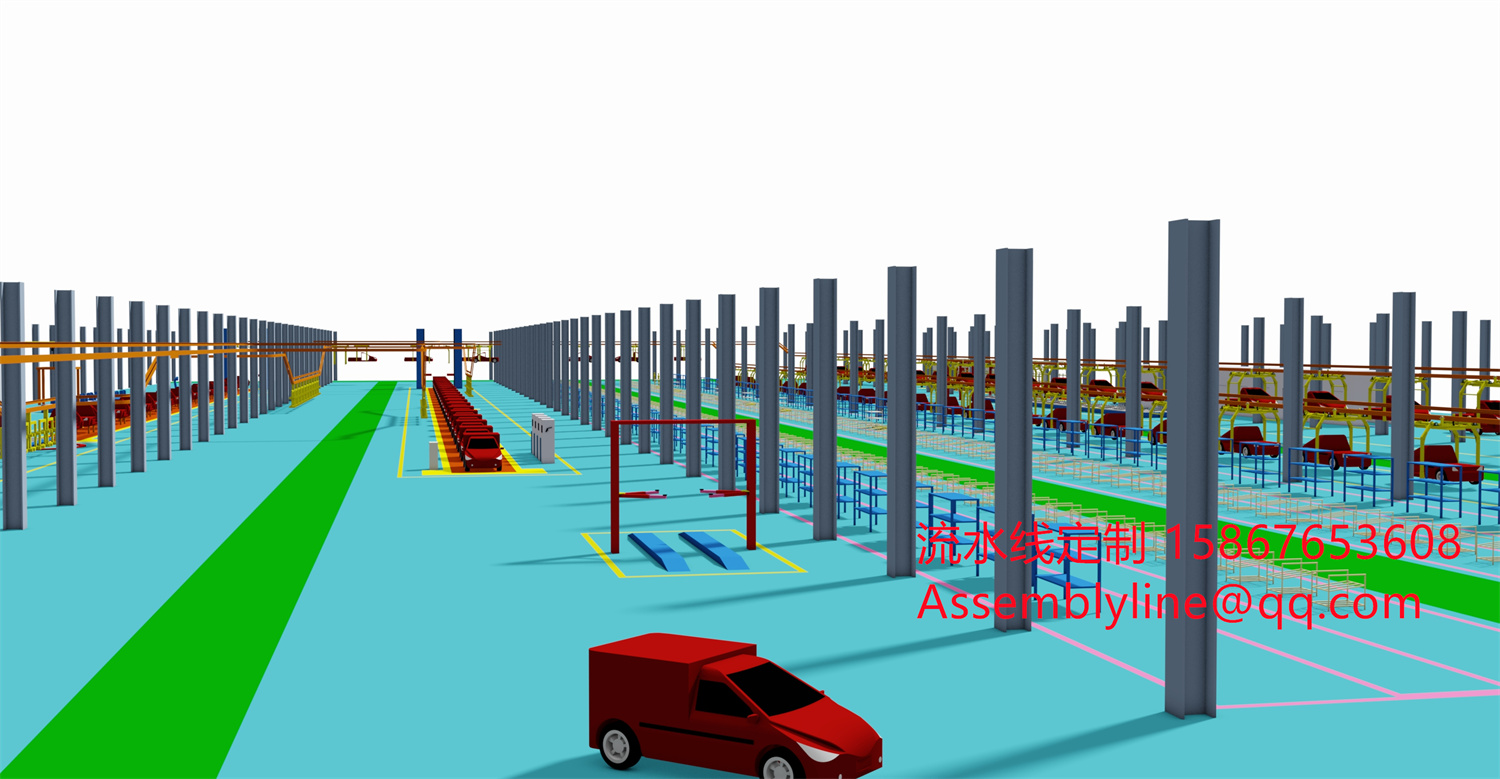

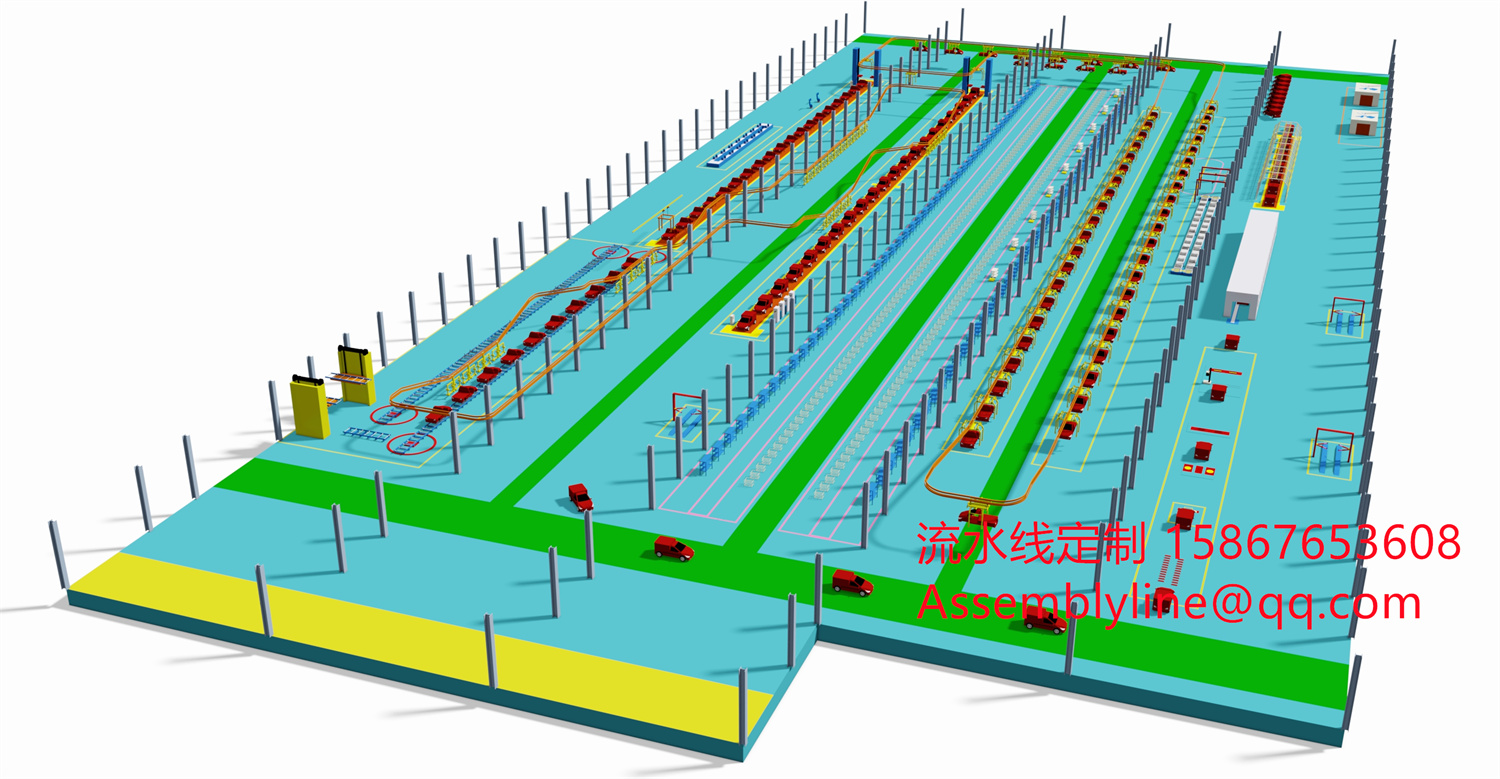

The assembly lines for electric vehicles (EVs) follow similar principles to traditional vehicles in the SKD (Semi-Knocked Down) and CKD (Completely Knocked Down) assembly forms, but they also incorporate adjustments and optimizations for the unique components of electric vehicles.

SKD Form

The SKD form refers to the major assemblies of a vehicle, such as the powertrain, cabin, and chassis, which are already manufactured abroad and then imported to the destination country. In the local factory, these assemblies are further assembled into a complete vehicle. For electric vehicles, this means that key components like the battery pack, electric motor, and electronic control system may already be pre-assembled or partially assembled, and then the final assembly work is completed in the destination country.

CKD Form

The CKD form involves importing the vehicle's parts completely disassembled and completing all the production processes in the destination country, including welding, painting, and assembly. For electric vehicles, this may include the assembly of battery modules, the installation of electric motors, and the integration of the electronic control system. The CKD model helps to enhance the technical level of the local automotive industry, promote industrial upgrading, and increase the localization rate.

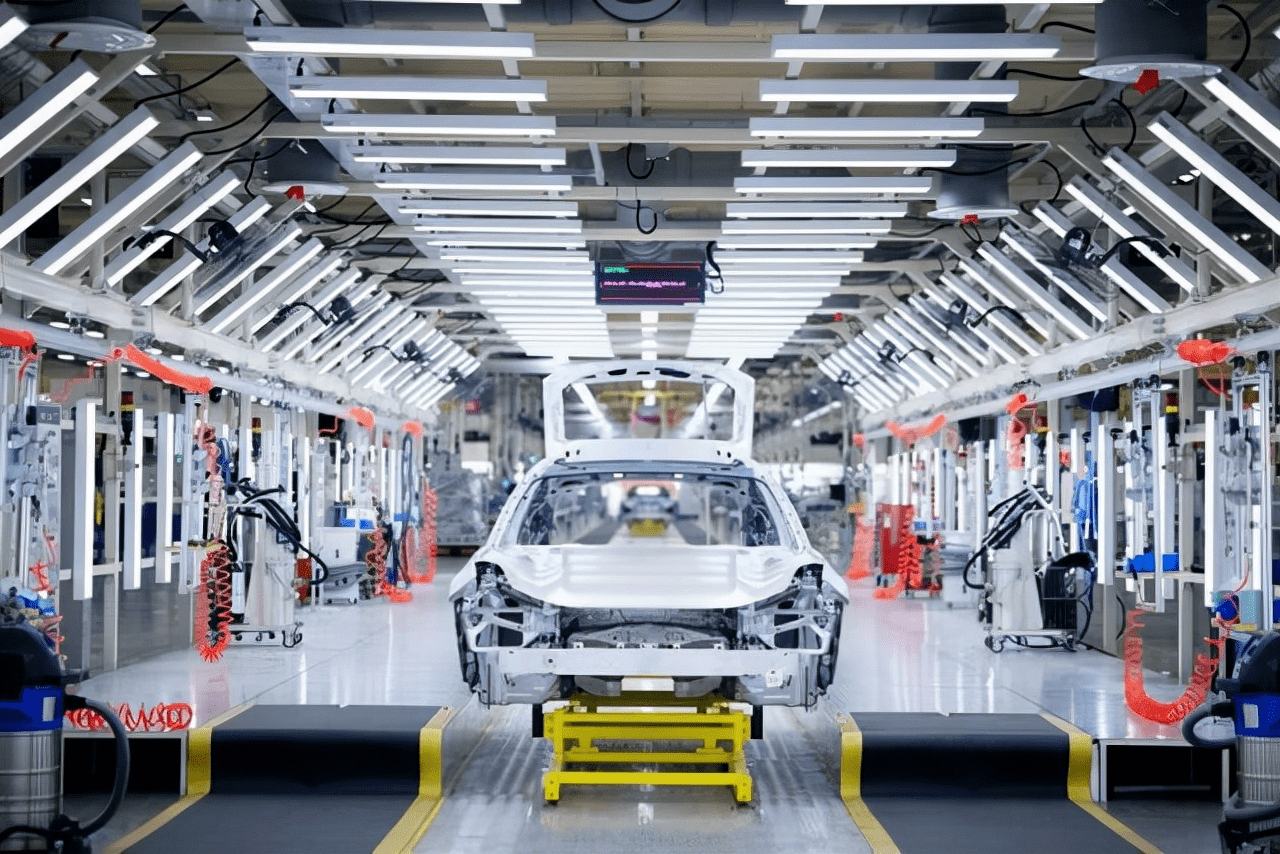

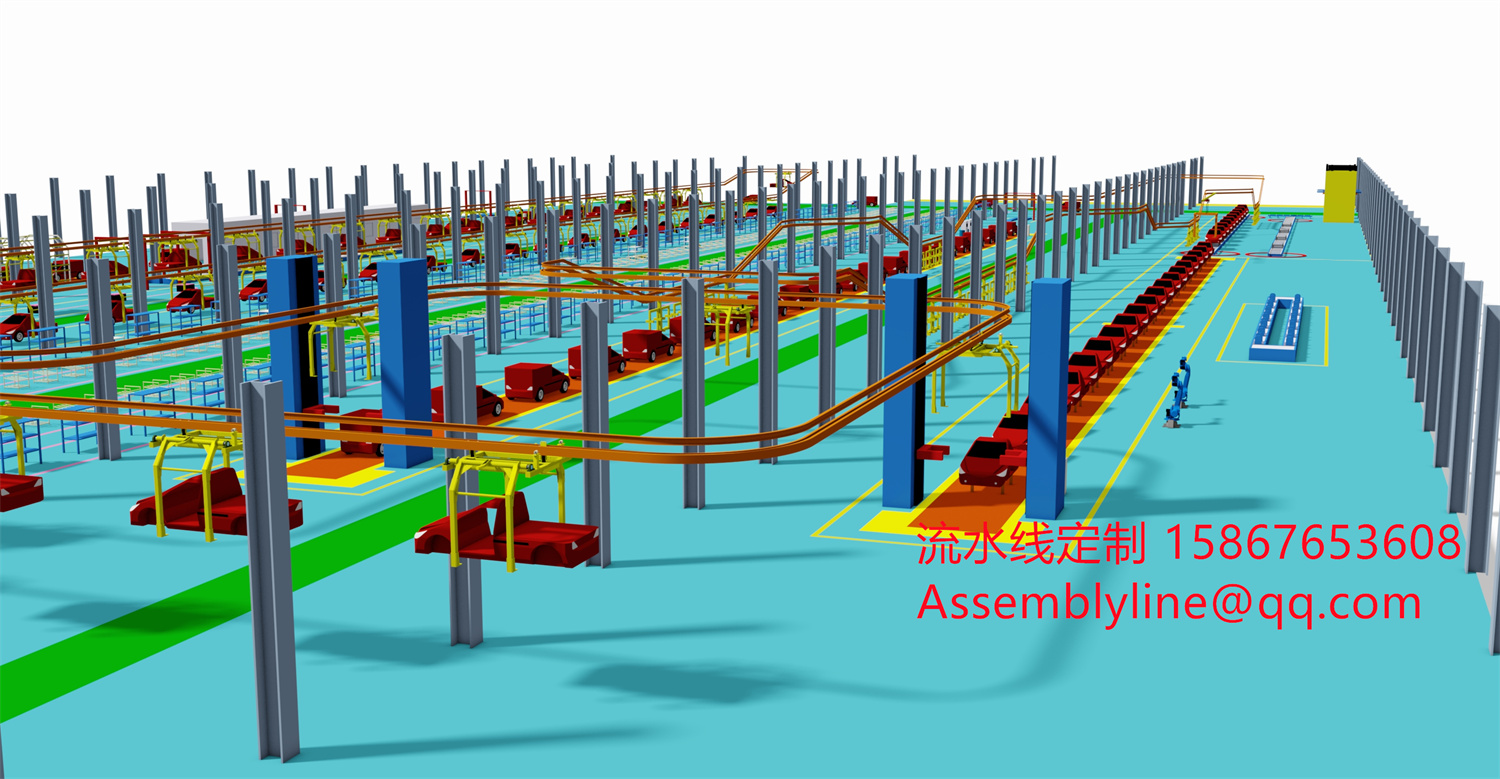

In the assembly process of electric vehicles, special attention needs to be paid to the inspection of the electric drive system and high-voltage electrical system, which is significantly different from the inspection of traditional vehicles. The assembly line for electric vehicles needs to strengthen the inspection of electrical performance and electrical safety to ensure the performance and safety of electric vehicles.

In addition, with the development of electric vehicle technology, digital technology, intelligent manufacturing technology, and 3D printing technology will also be widely applied in the assembly lines of electric vehicles to improve production efficiency and product quality.

In summary, the SKD and CKD forms of electric vehicle assembly lines need to adapt to the unique production requirements of electric vehicles, including the integration of the electric drive system, the inspection and assembly of batteries and electronic control systems, and to adapt to the trends of environmental protection and energy saving.

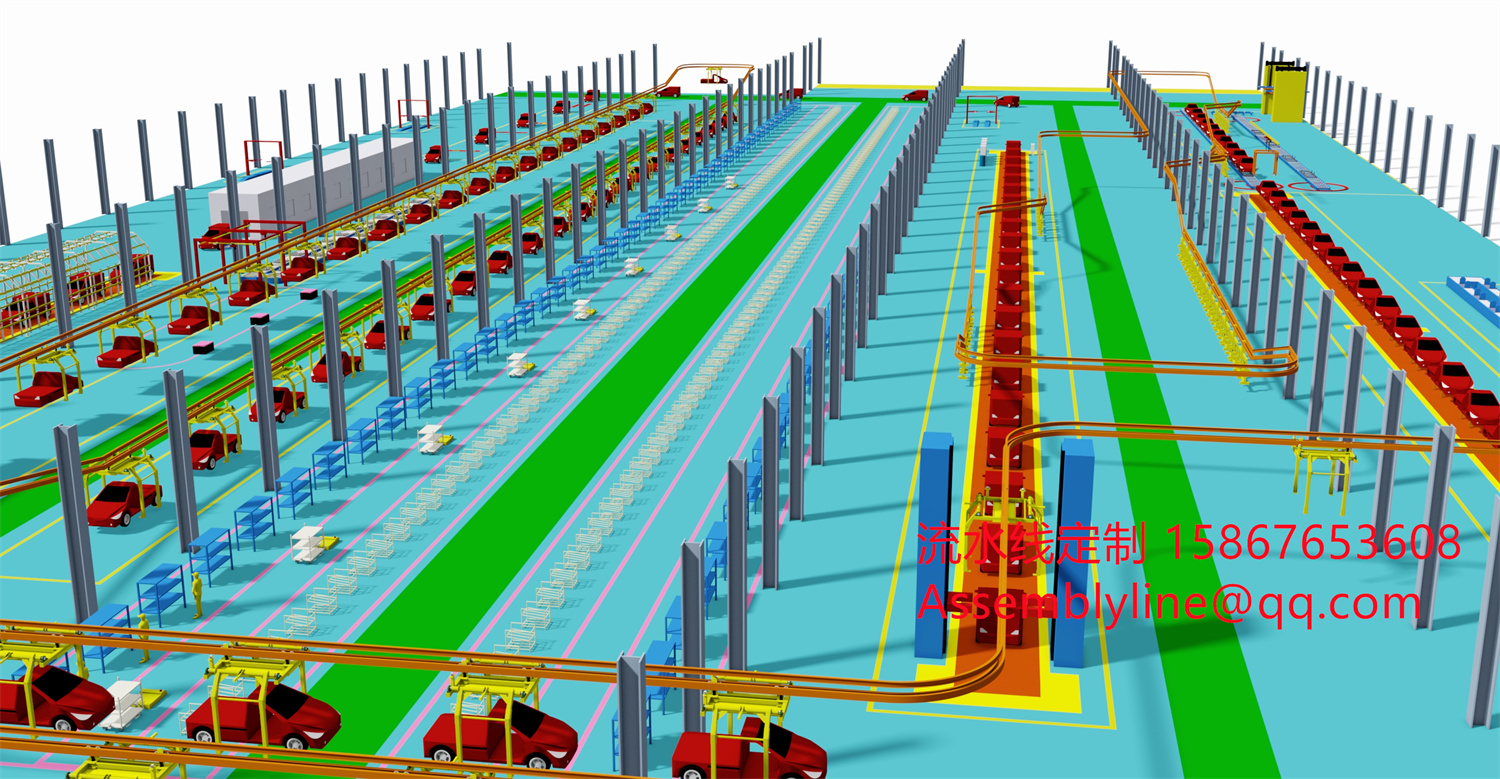

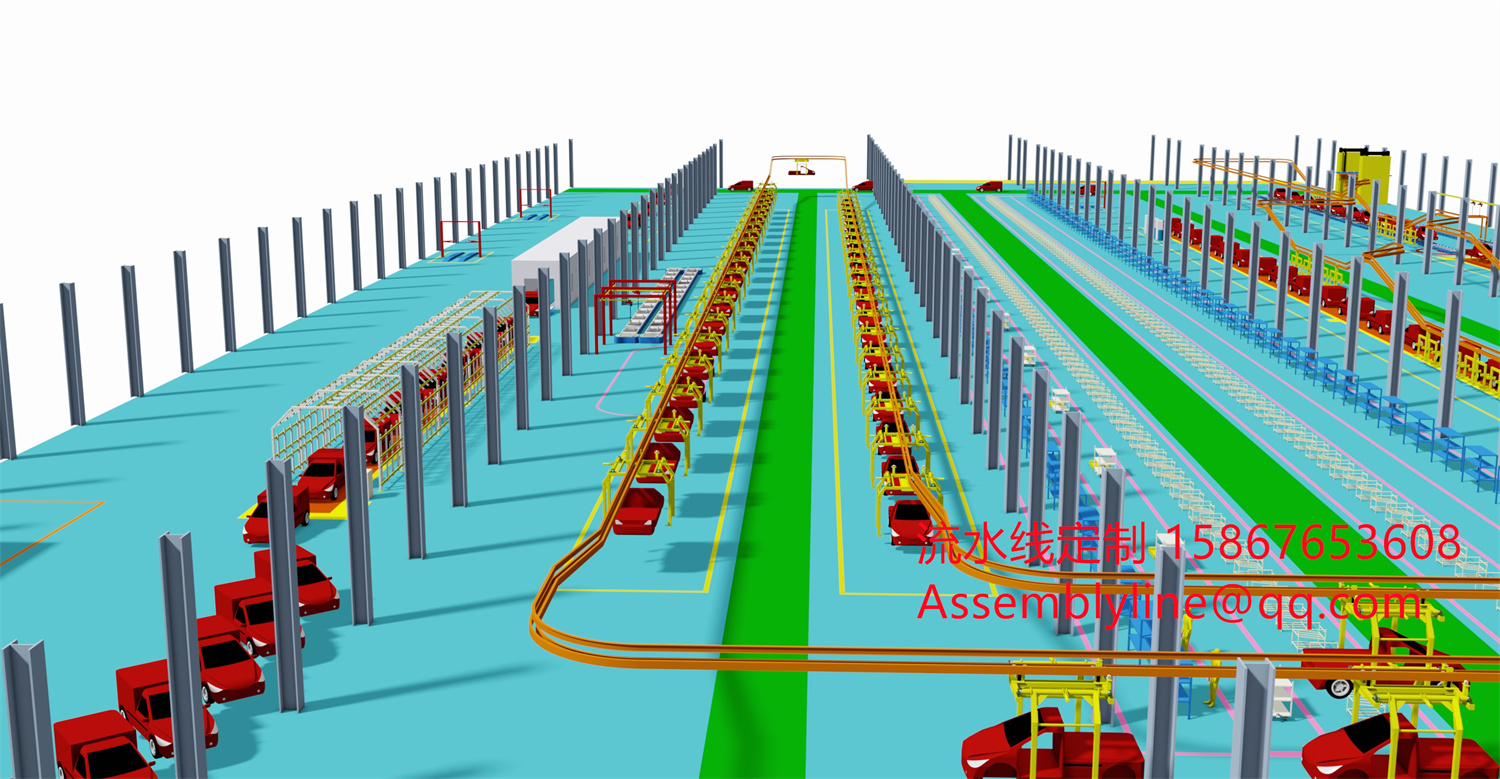

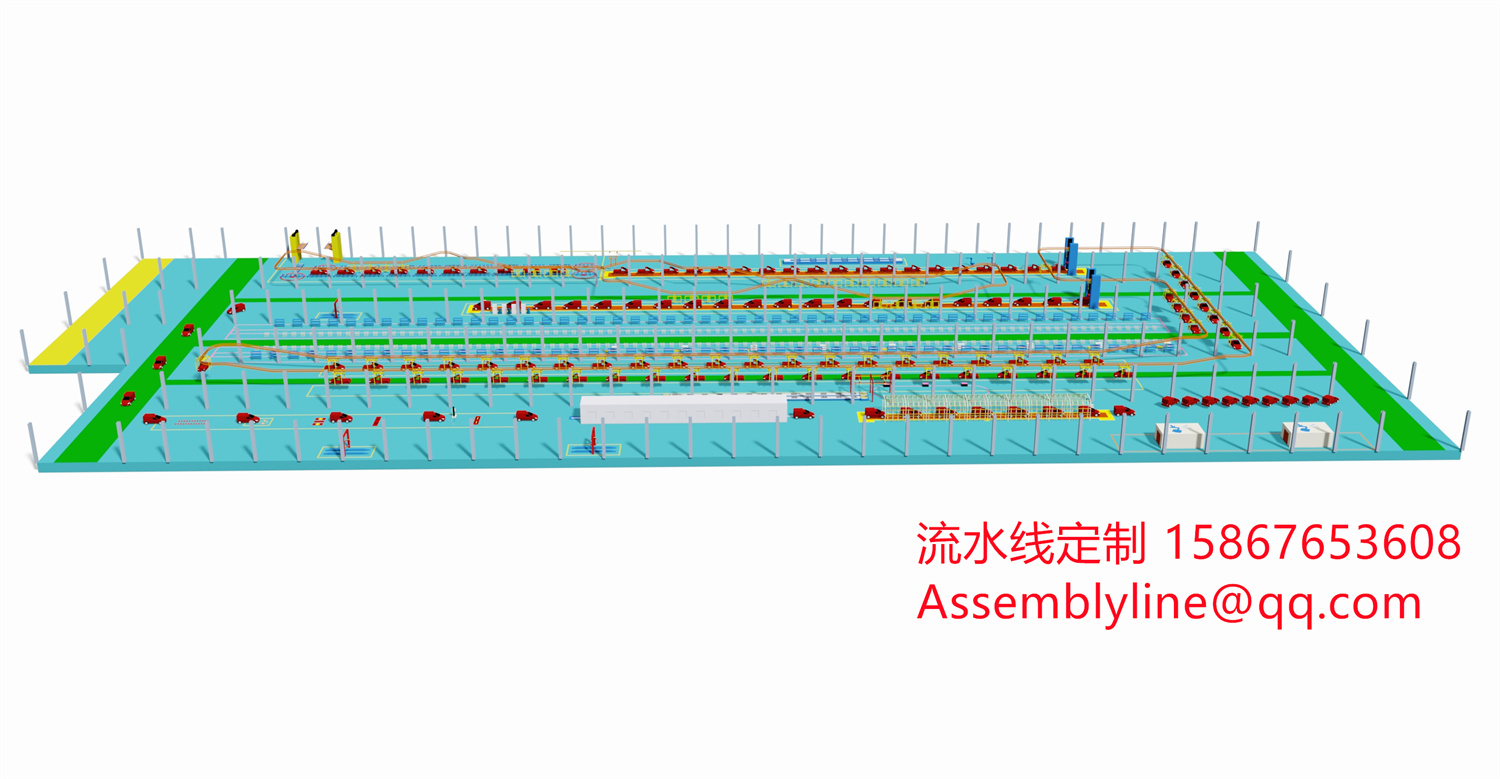

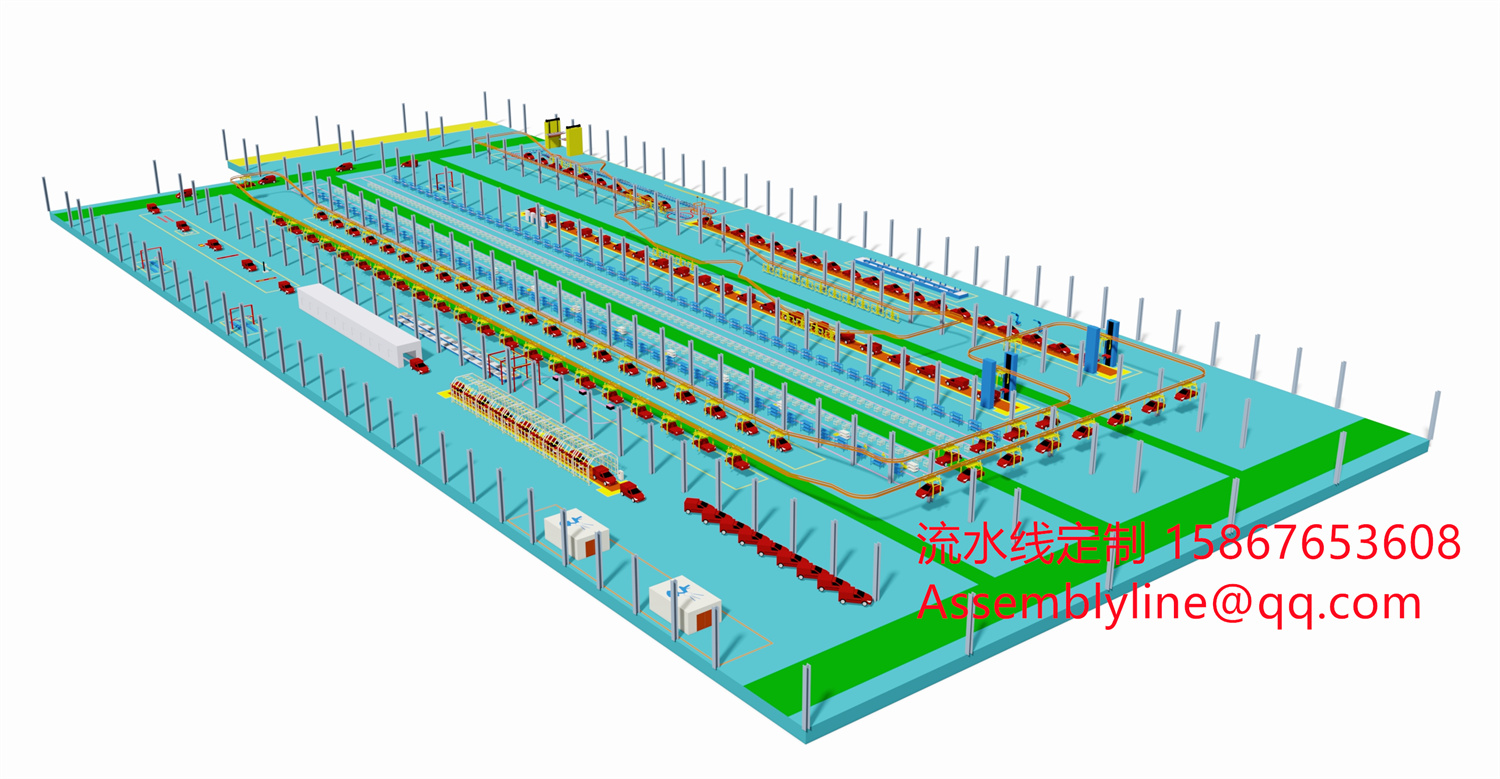

The electric vehicle (EV) assembly line is a highly automated production line specifically designed for manufacturing electric vehicles, with the following notable characteristics: It integrates key processes such as battery assembly, electric motor, and electronic control system assembly; adopts a modular design for flexibility in producing different vehicle models; includes stringent quality control and safety inspection procedures to ensure the performance and safety of electric vehicles; focuses on environmental protection and energy conservation by reducing energy consumption and waste during production; utilizes digital technology and intelligent manufacturing to enhance production efficiency and product quality; and is designed to be adaptable to meet diverse market demands, with the capability for continuous improvement to keep pace with the rapid development of electric vehicle technology.

Electric vehicles EV assembly line Plant SKD CKD

Factory address: East Industrial Cluster, Wenling City, Zhejiang Province

Aircraft: Taizhou Luqiao Airport (1 hour) Wenzhou Airport (2 hours)

High speed rail: Wenling Station (40 minutes)

Expressway intersection: Wenling North (15 minutes) Wenling East (20 minutes)

Contact our engineering team and get company info

Email: Assemblyline@qq.com