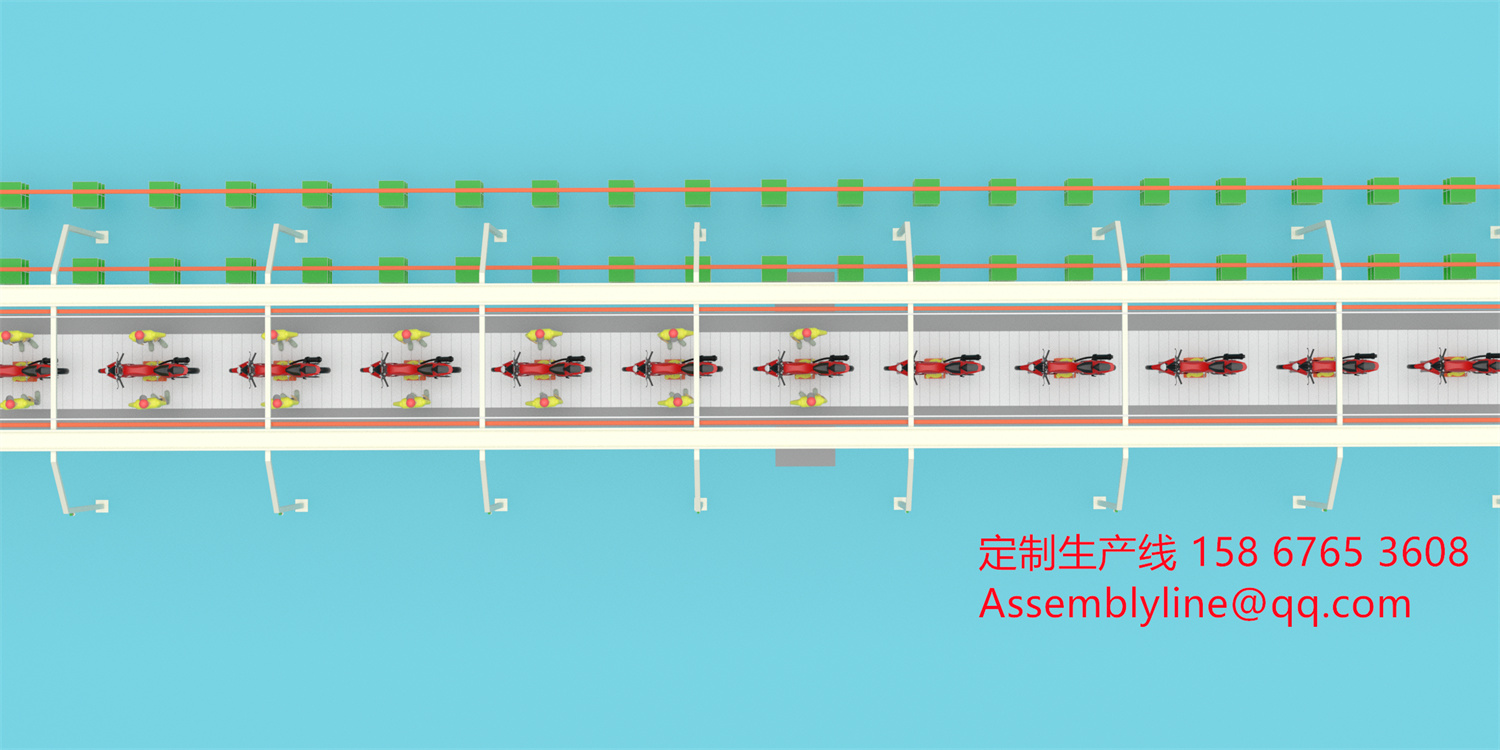

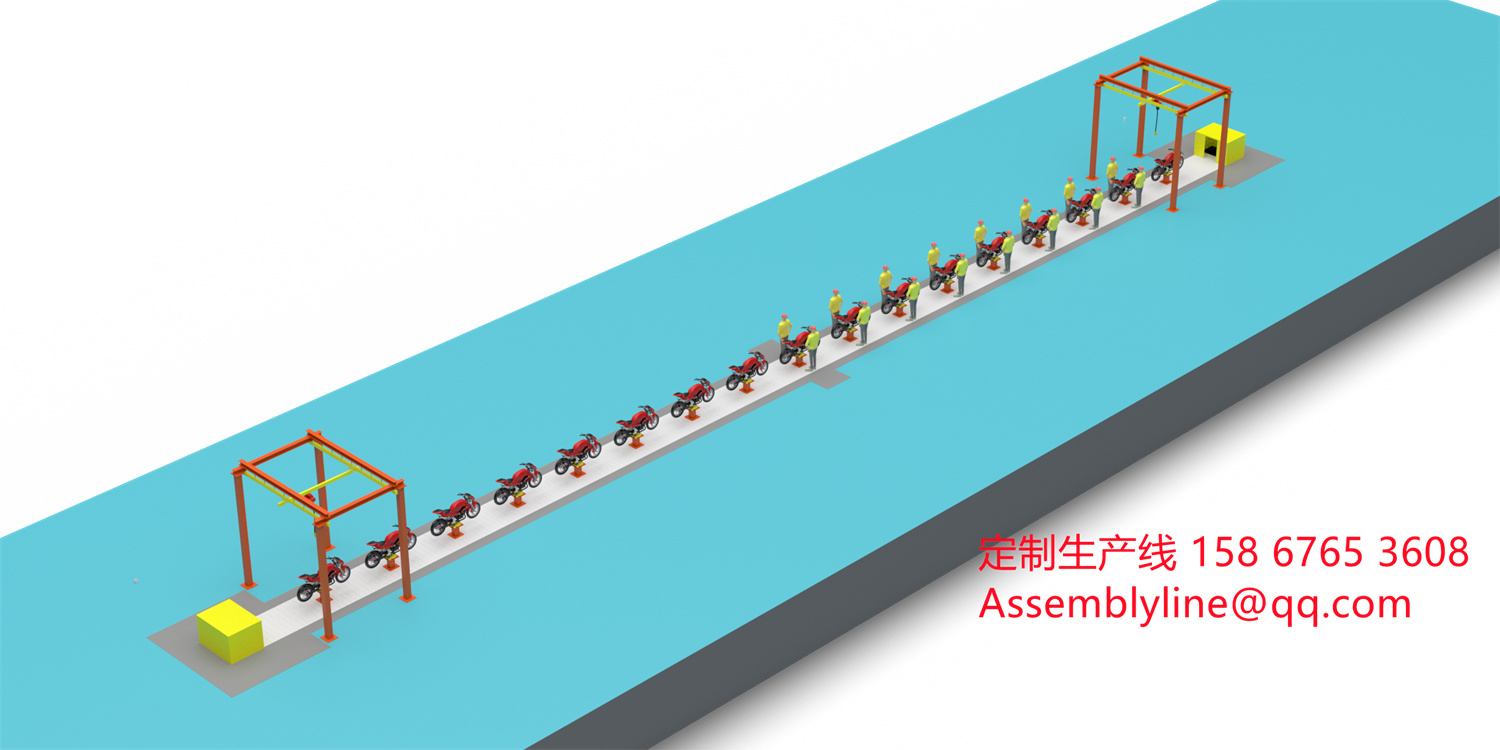

A motorcycle assembly line typically includes the following equipment:

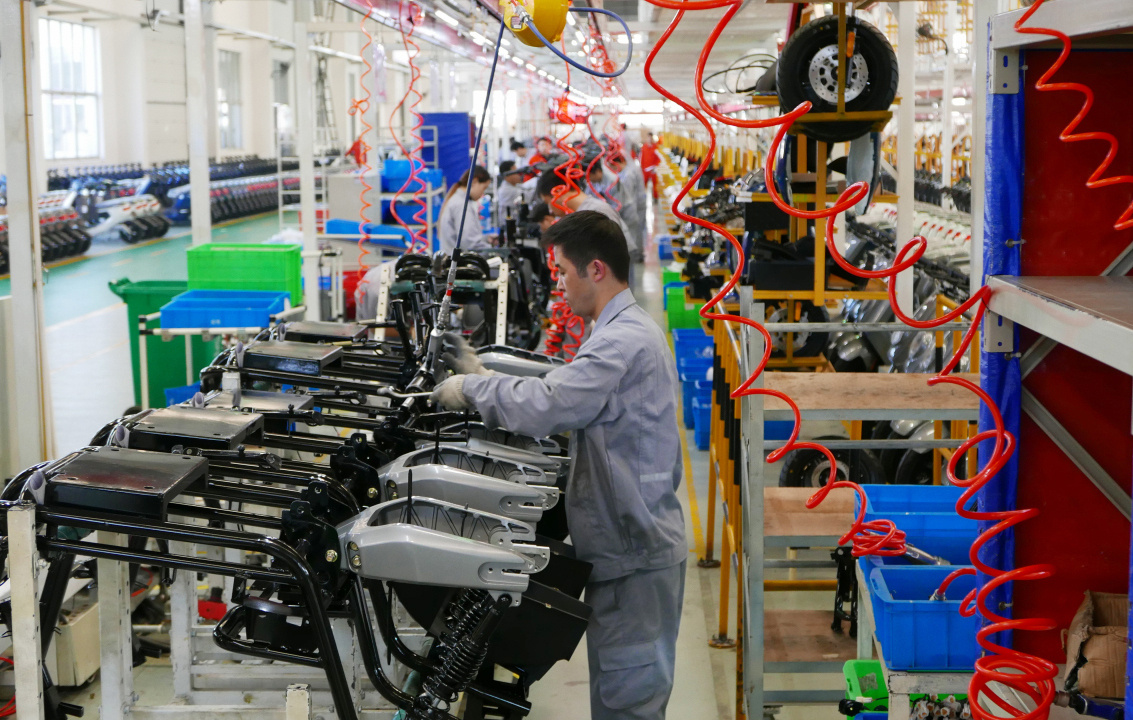

1.Assembly Stations: The most basic equipment on the motorcycle final assembly line, providing a working platform for assembling various parts into the final product.

2.Electric and Pneumatic Tools: Used for the assembly and disassembly of bolts and nuts, improving work efficiency and accuracy while reducing physical effort.

3.Rotating Platforms: Used to rotate motorcycles for assembly from different directions and angles, enhancing the flexibility and accuracy of assembly.

4.Quality Inspection Equipment: Detects key parameters such as appearance, size, and durability to ensure each motorcycle meets quality standards.

5.Automation Equipment: Improves production efficiency and consistency, reducing human errors and labor intensity, such as automated assembly robots and automatic inspection devices.

6.Conveying Systems: Such as chain plate drags that move workpieces in a flat transport motion to achieve the purpose of production technology.

7.Standard Configurations like Lighting, Fans, and Tooling: Provide the necessary working environment and tools for the production line.

These pieces of equipment work together to ensure the efficient operation and product quality of the motorcycle assembly line.

The number of motorcycles a production line can produce each day depends on various factors, including:

1.Degree of Automation: Highly automated production lines can typically produce more motorcycles.

2.Worker Skills and Efficiency: Skilled workers can complete assembly tasks more quickly.

3.Production Process Design: An optimized production process can reduce waiting and idle times.

4.Equipment Performance and Reliability: High-performance and reliable equipment can reduce downtime and breakdowns.

5.Material Supply and Inventory Management: Timely material supply and effective inventory management can prevent production interruptions.

6.Production Planning and Scheduling: Reasonable production planning and scheduling can maximize the utilization rate of the production line.

7.Product Complexity: Producing more complex or customized motorcycles may take more time.

8.Work Shifts: Multiple shifts can increase the production time each day.

9.Quality Control: Strict quality control may reduce production speed but can improve product quality.

10.Market Demand: Adjust production volumes according to market demand.

Generally, an efficient motorcycle production line can produce dozens to hundreds of motorcycles each day, but this requires a comprehensive consideration of the factors mentioned above. Some advanced production lines can even reach a production capacity of thousands of motorcycles per day, especially when mass-producing standard models.

Please note that these figures are rough estimates, and the actual production capacity needs to be determined based on the specific circumstances of the production line.

The motorcycle assembly line is designed to accommodate the assembly and production of a variety of motorcycles, including standard, cruiser, sport, off-road, electric, three-wheeled, retro, custom, and scooter models. With a flexible and modular production line layout, it meets the manufacturing needs for different models and configurations of motorcycles.

Motorcycle assembly lines enhance production efficiency through the implementation of automation, modular design, lean manufacturing principles, stringent quality control, employee training, equipment maintenance, process optimization, material management, application of information technology, and the design of flexible production lines. These methods significantly improve efficiency, reduce costs, and ensure product quality to meet market demands and enhance competitiveness.

Factory address: East Industrial Cluster, Wenling City, Zhejiang Province

Aircraft: Taizhou Luqiao Airport (1 hour) Wenzhou Airport (2 hours)

High speed rail: Wenling Station (40 minutes)

Expressway intersection: Wenling North (15 minutes) Wenling East (20 minutes)

Contact our engineering team and get company info

Email: Assemblyline@qq.com