ATVs (All-Terrain Vehicles) and UTVs (Utility Terrain Vehicles) are two different types of off-road vehicles, each with their own characteristics in terms of categories, structure, assembly production processes, and automated production lines:

- Categories:

- ATV: Typically refers to small off-road motorcycles with either three or four wheels, designed for one or two riders.

- UTV: These are four-wheel drive vehicles, usually with more seating space and passenger capacity, designed for carrying people or cargo.

- Structure:

- ATV: Lighter in structure, designed for agility, often with a higher ground clearance and narrower tires to enhance off-road capabilities.

- UTV: More robust in structure, with wider tires and greater load capacity, typically equipped with roll cages and more comfortable seating.

- Assembly Production Process:

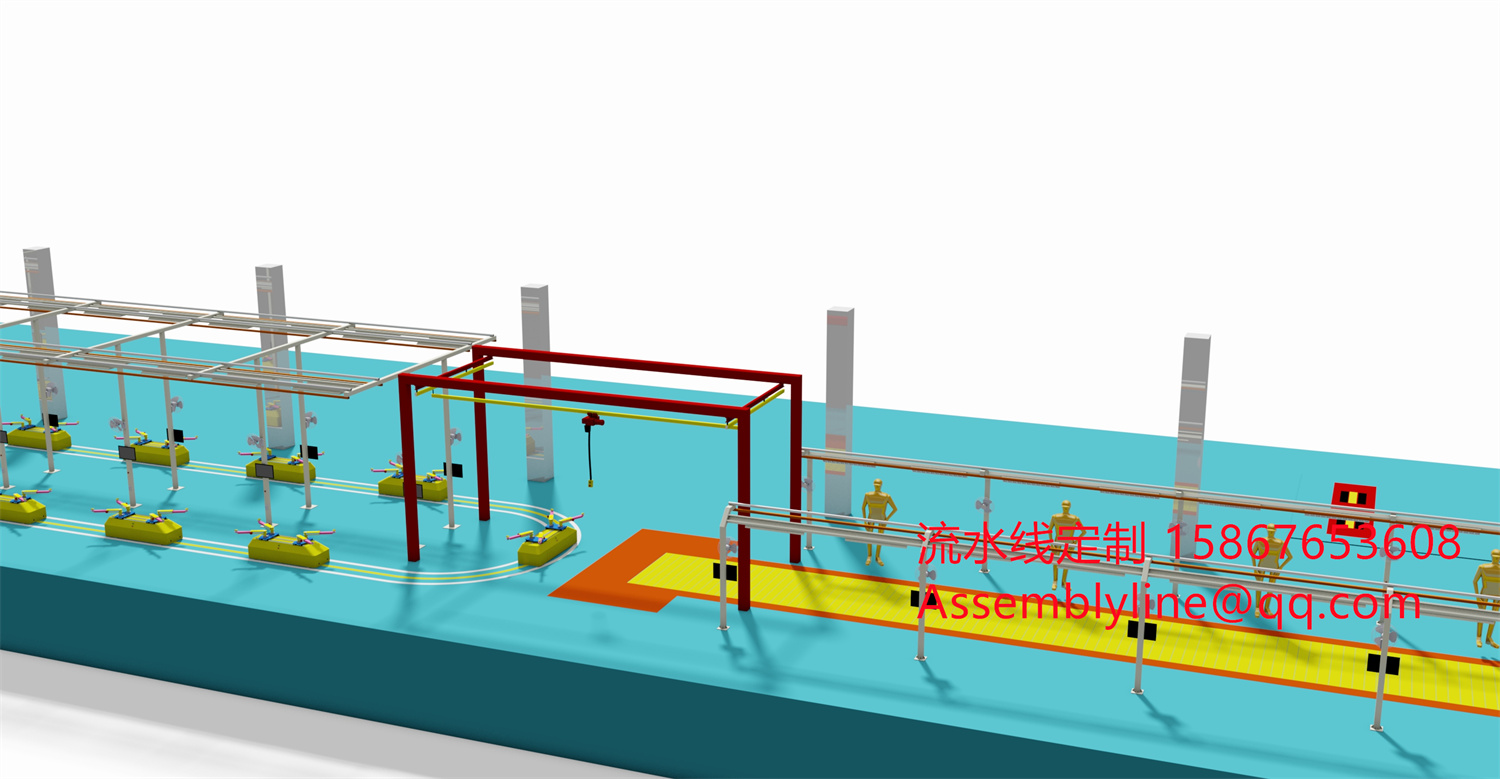

- Chassis Assembly: Including the assembly of the frame, suspension system, and powertrain.

- Power System Installation: The installation of the engine and transmission.

- Body Assembly: The installation of seats, dashboards, and body panels.

- Electronic System Installation: The installation of electrical wiring, sensors, and control units.

- Final Inspection and Testing: To ensure all parts are correctly installed and functioning properly.

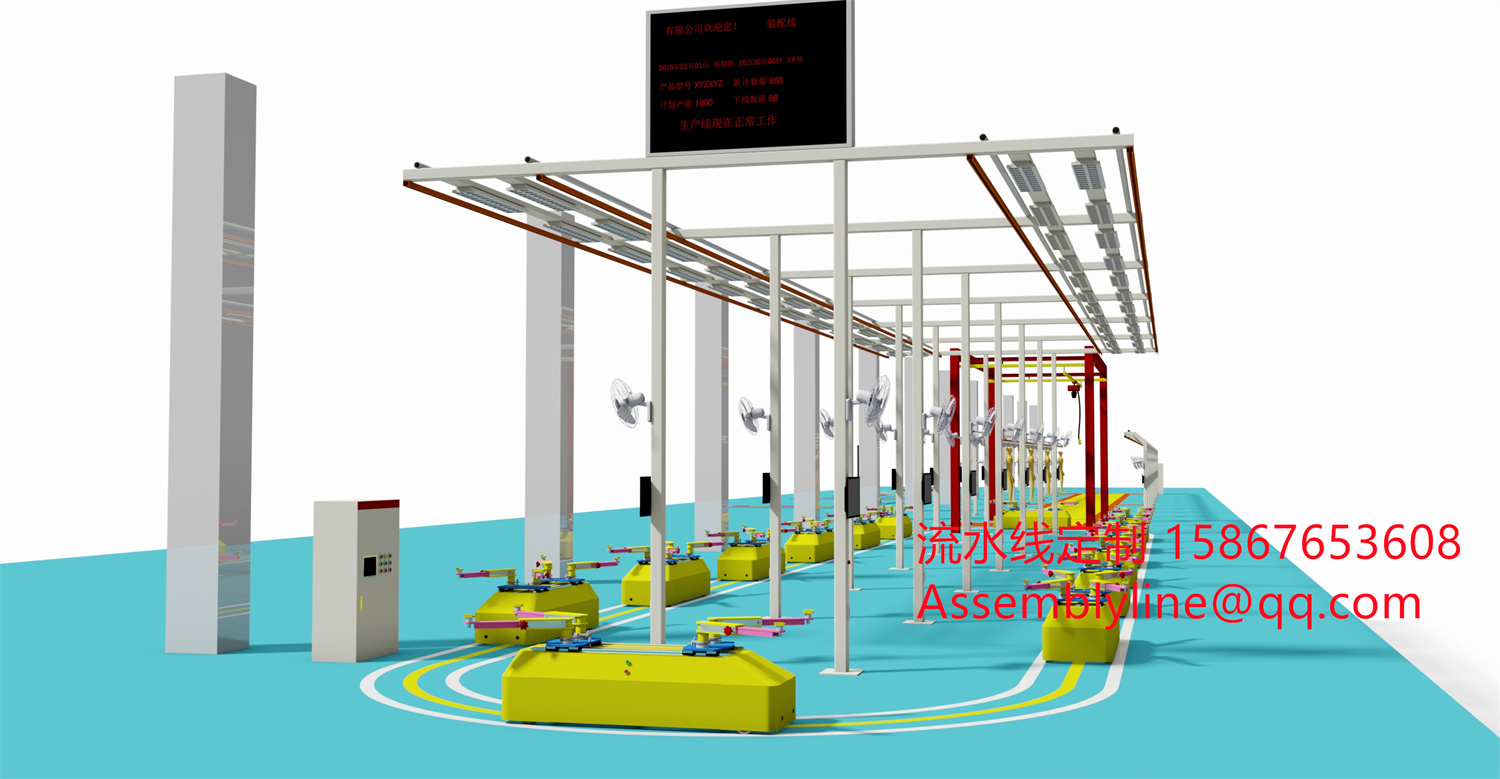

- Automated Production Line:

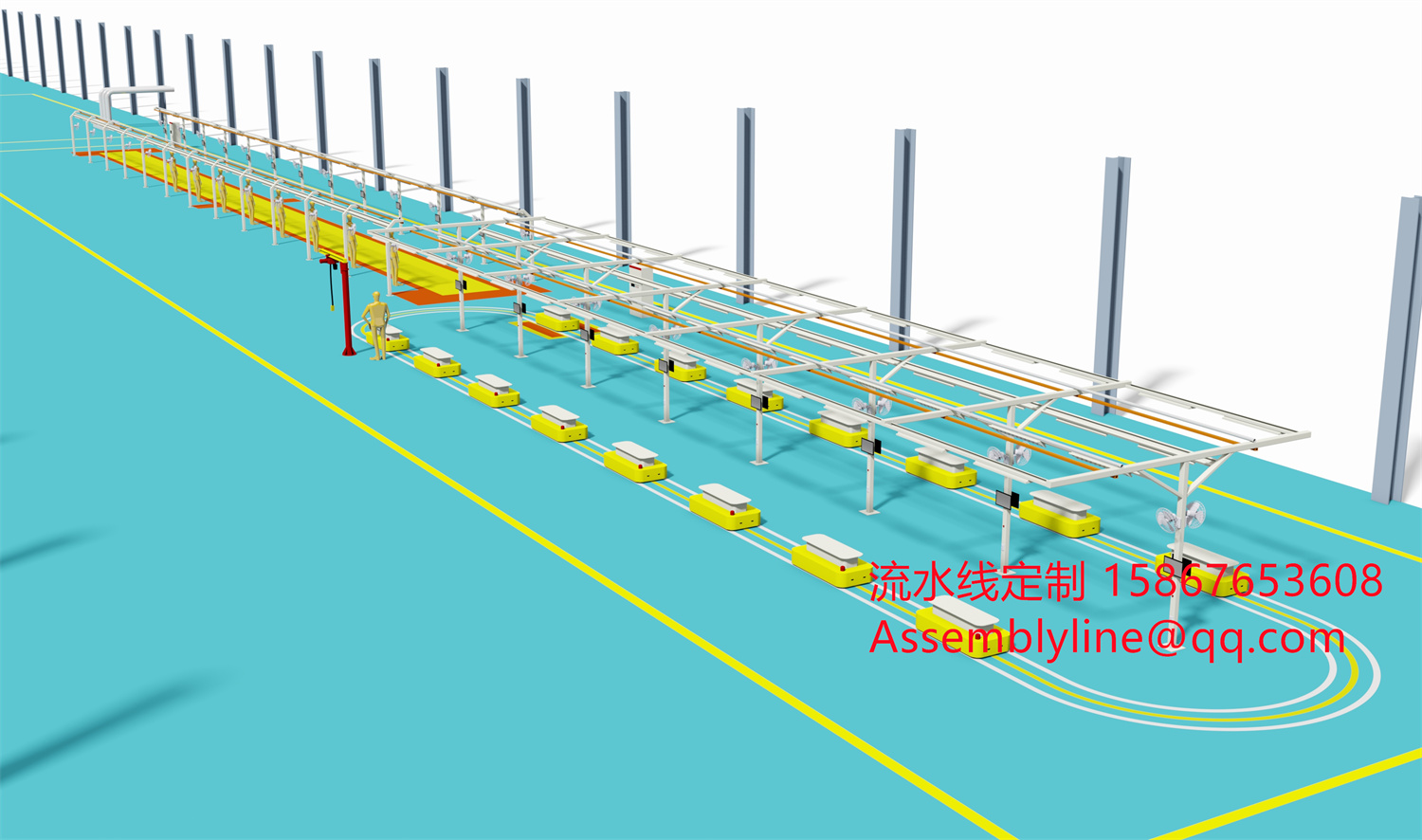

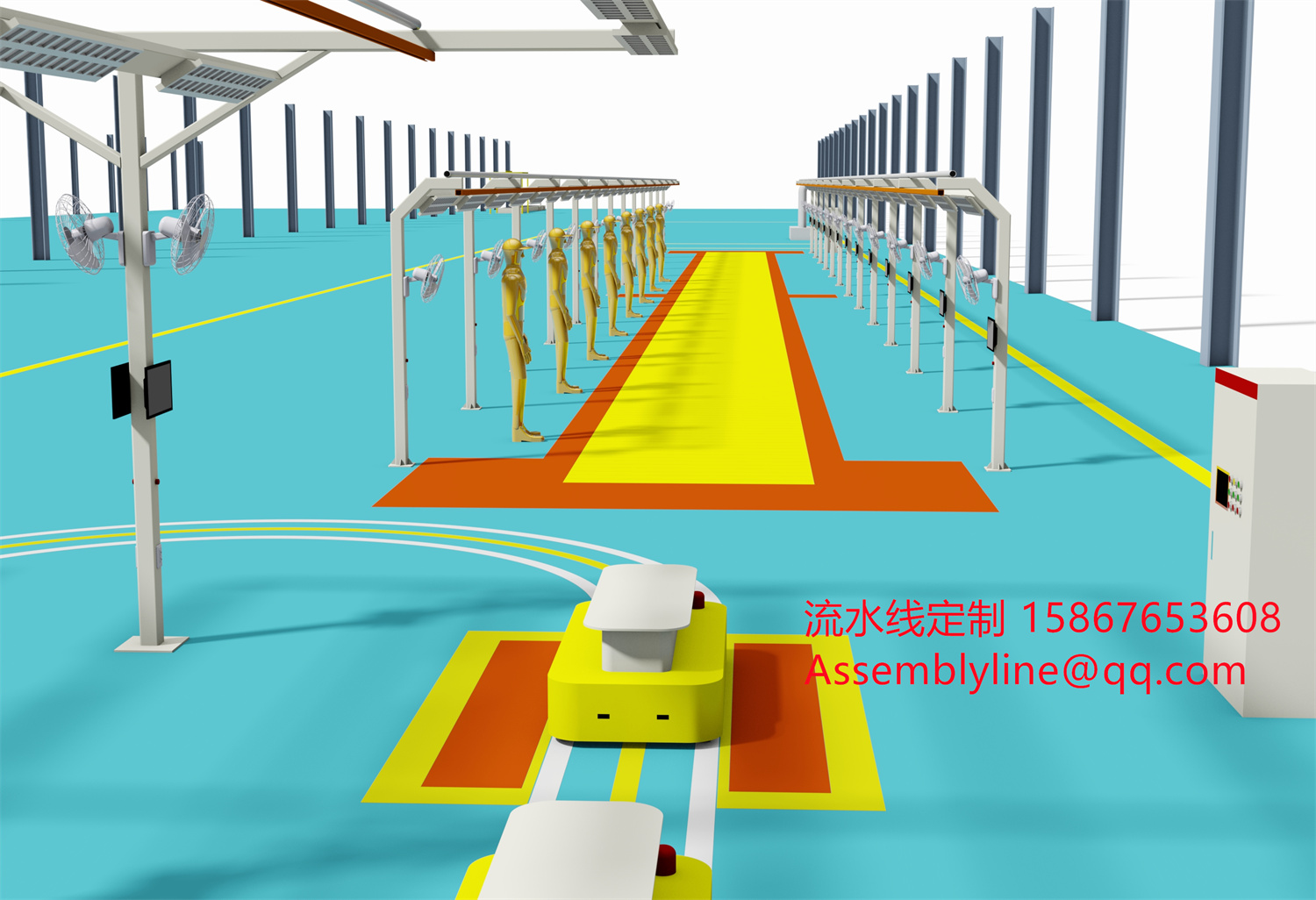

- Automated Conveyance System: Used to move the vehicle chassis or body along the production line.

- Robotic Welding: Automated welding robots for precise welding of frames and other metal parts.

- Automated Assembly Line: Mechanical arms and other automated equipment for part assembly.

- Quality Control: Automated inspection equipment for detecting defects in the production process.

- Painting Line: Automated painting systems for vehicle painting and baking.

These processes and production line designs aim to improve production efficiency, ensure product quality, and reduce manual operations, thereby reducing costs and increasing production speed. With technological advancements, the production lines for ATVs and UTVs may further integrate more automation and intelligent technologies.

Using an assembly line for the production of ATVs (All-Terrain Vehicles) and UTVs (Utility Terrain Vehicles) offers the following benefits:

- Increased Efficiency: The assembly line significantly boosts production efficiency as each worker or machine focuses on specific tasks, reducing the time spent switching between tasks.

- Cost Reduction: Automation and specialization in the assembly line can reduce labor costs and lower per-unit costs through mass production.

- Quality Control: The assembly line allows for strict quality control measures to be implemented during the production process, ensuring the consistency and reliability of each component and the entire vehicle.

- Error Reduction: Standardized production processes reduce the likelihood of human errors, improving product uniformity and quality.

- Ease of Maintenance: Maintenance of the assembly line is relatively straightforward as each stage has a clear function and responsibility.

- Flexibility: Although designed for specific processes, many assembly lines have a certain degree of flexibility and can be adjusted according to production needs.

- Rapid Market Response: The assembly line can quickly adjust production plans to adapt to changes in market demand, such as increasing or decreasing the production of specific models.

- Skill Improvement for Workers: Assembly line work allows workers to focus on improving specific skills, thereby enhancing the overall professional level of the production team.

- Material Waste Reduction: Through precise planning and control, the assembly line can reduce material waste and improve material utilization rates.

- Environmentally Friendly: The high efficiency and waste reduction of the assembly line help to minimize the environmental impact, aligning with sustainable development requirements.

- Promoting Technological Innovation: Continuous improvement of the assembly line can promote the development of new technologies and processes, further enhancing production efficiency and product quality.

- Enhanced Competitiveness: By improving efficiency and reducing costs, assembly line production can enhance a company's market competitiveness.

Assembly line production is an effective method of production, especially suitable for products like ATVs and UTVs that require a lot of manual assembly and fine craftsmanship.

ATVs and UTVs offer a variety of models designed for different terrains and purposes, with ATVs typically being smaller and more agile, while UTVs are larger and more versatile. Structurally, ATVs feature a lightweight frame and high ground clearance, whereas UTVs have a robust frame with roll cages for safety. The production process involves chassis assembly, engine installation, body fitting, and electronic system integration. Automation in the form of robotic welding and assembly lines enhances efficiency and quality, with a focus on environmental sustainability and continuous innovation.

ATV UTV Production line Assembly line

Factory address: East Industrial Cluster, Wenling City, Zhejiang Province

Aircraft: Taizhou Luqiao Airport (1 hour) Wenzhou Airport (2 hours)

High speed rail: Wenling Station (40 minutes)

Expressway intersection: Wenling North (15 minutes) Wenling East (20 minutes)

Contact our engineering team and get company info

Email: Assemblyline@qq.com