The knowledge of motorcycle assembly production line layout in the factory workshop typically includes the following key points:

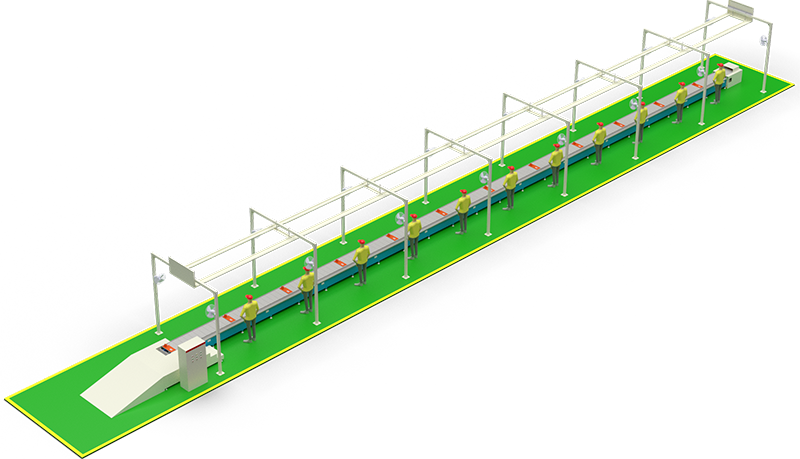

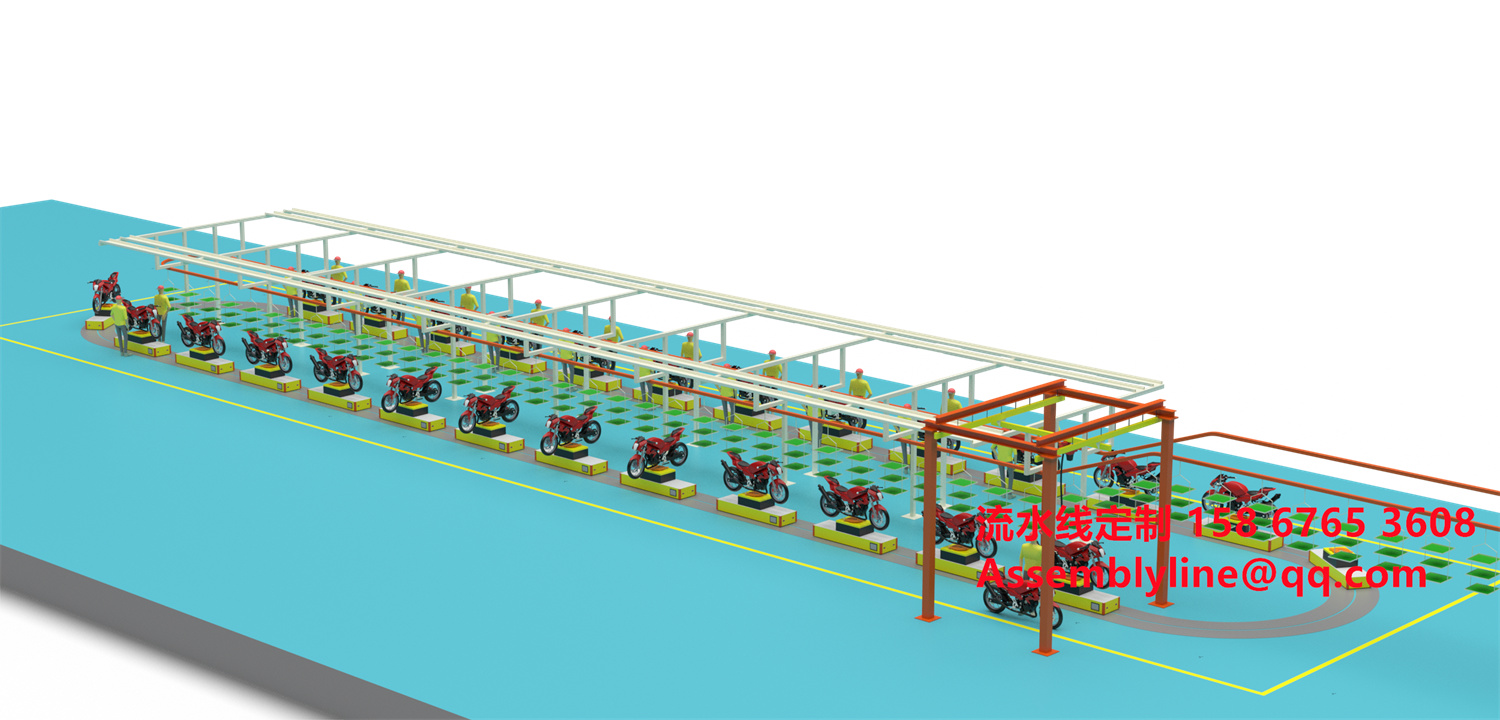

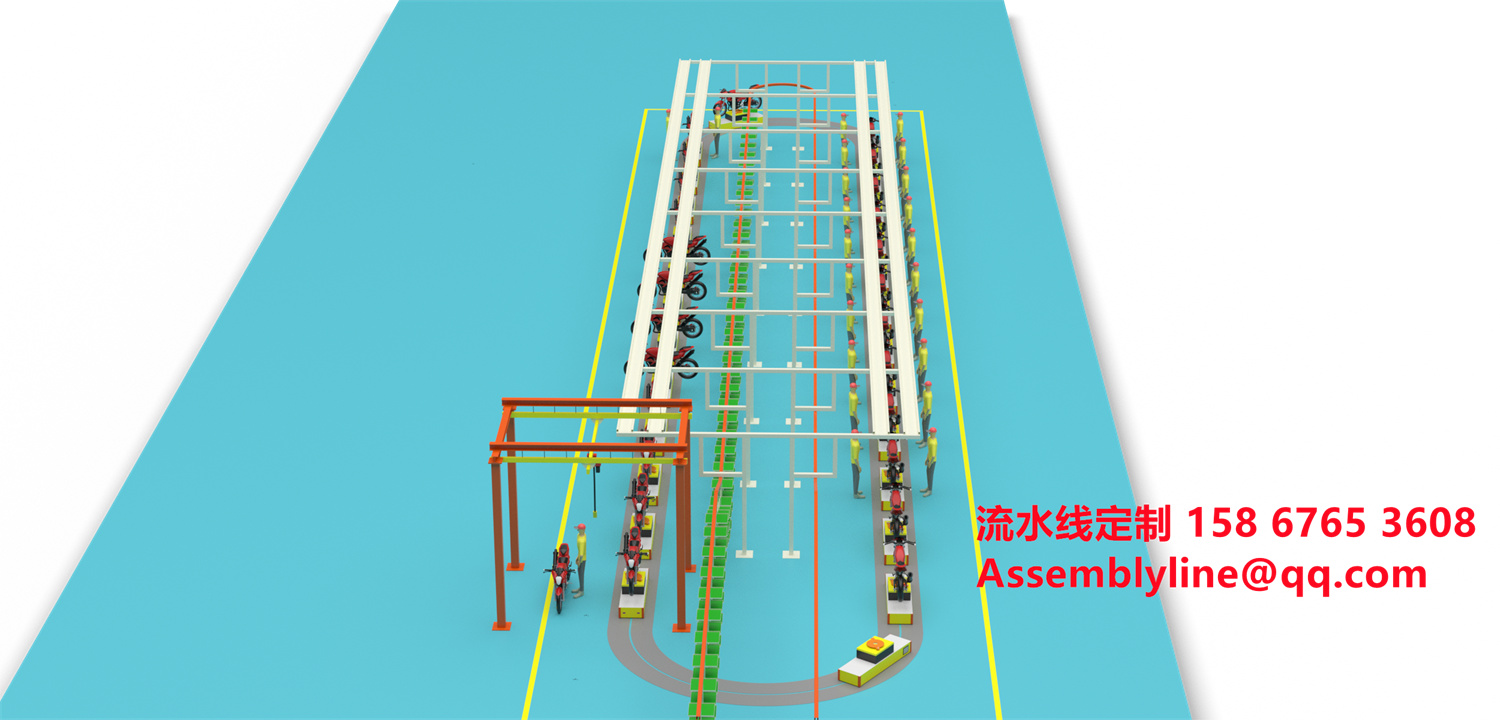

1.Process Optimization: The workshop layout should optimize the production process to ensure smooth connections between various assembly stations, reducing material handling time and distance.

2.Modular Layout: Adopt a modular layout that allows the production line to be flexibly adjusted according to production needs, accommodating the assembly of different motorcycle models.

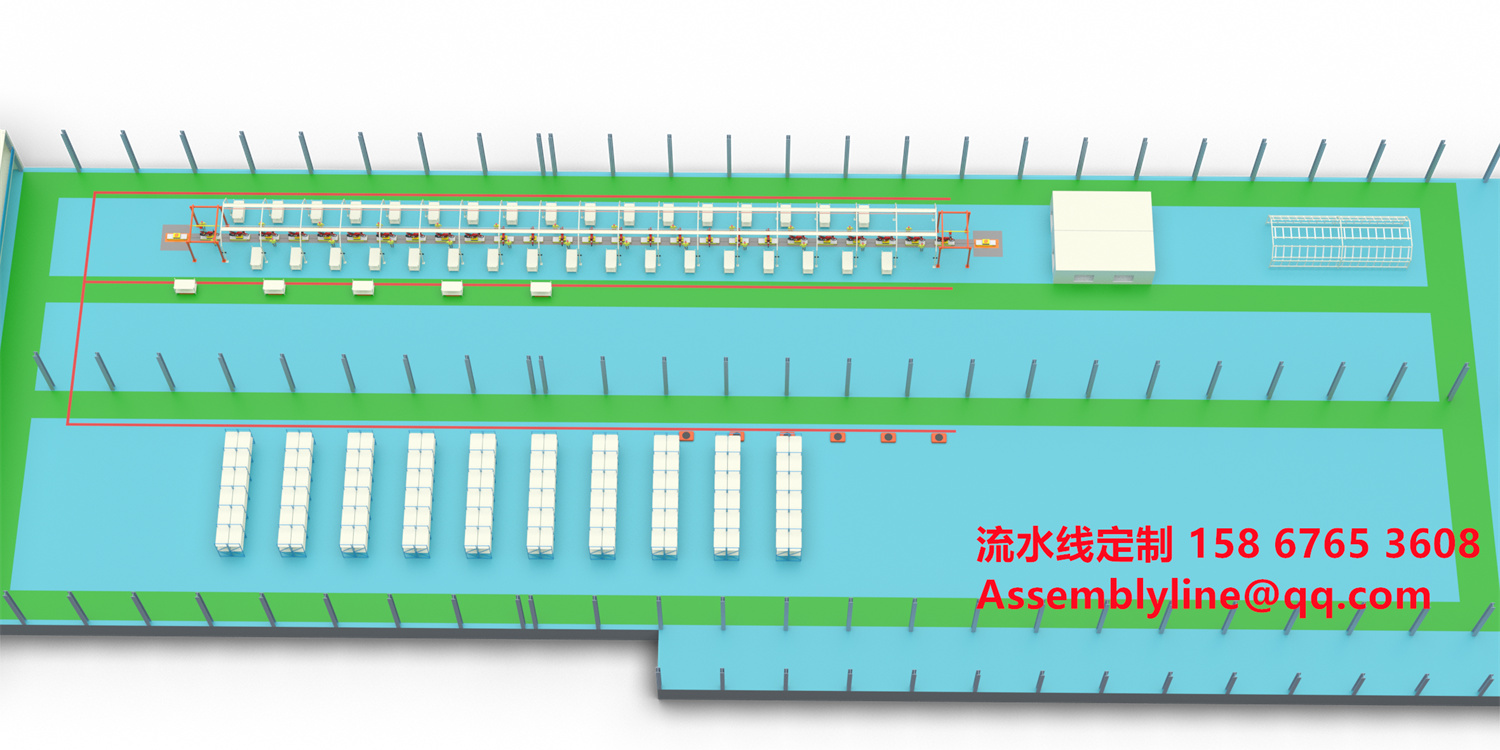

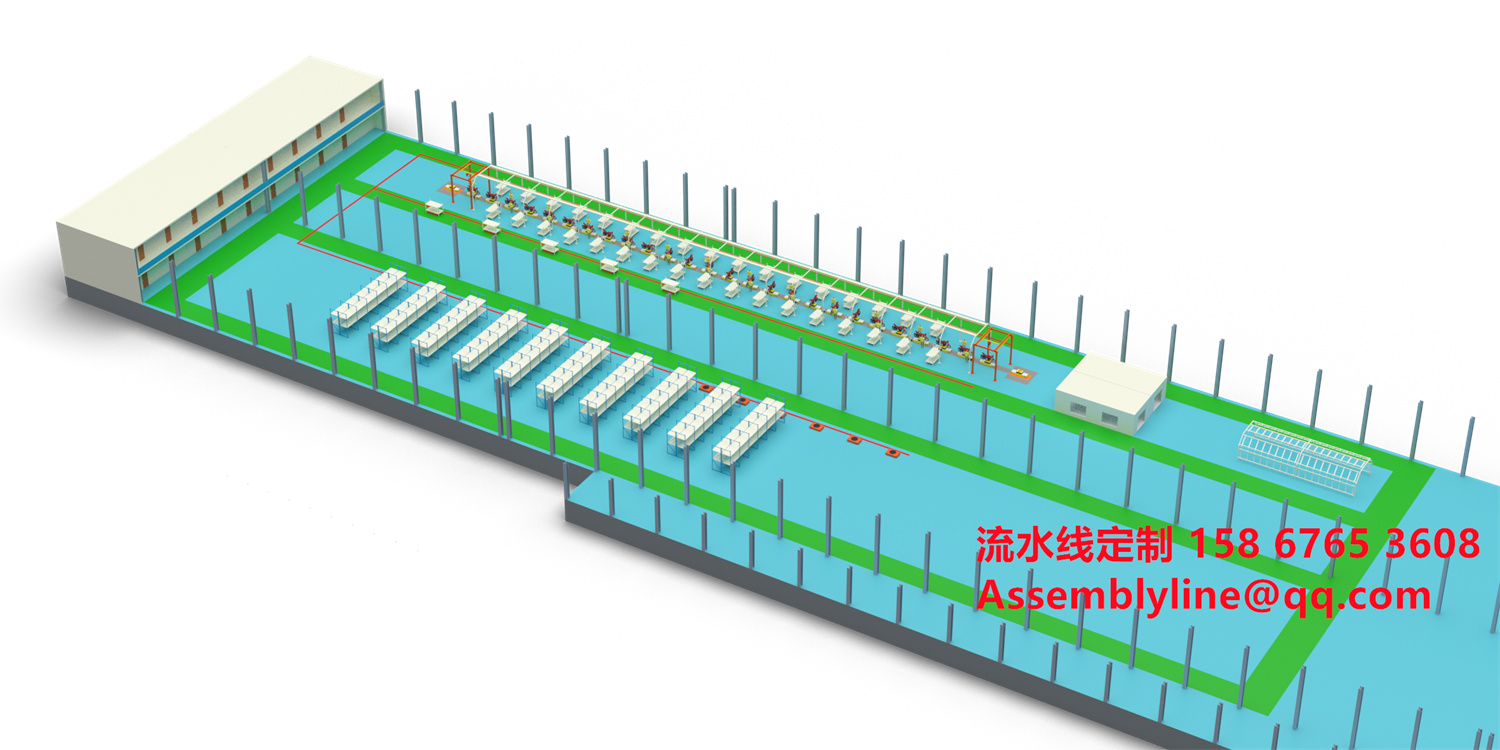

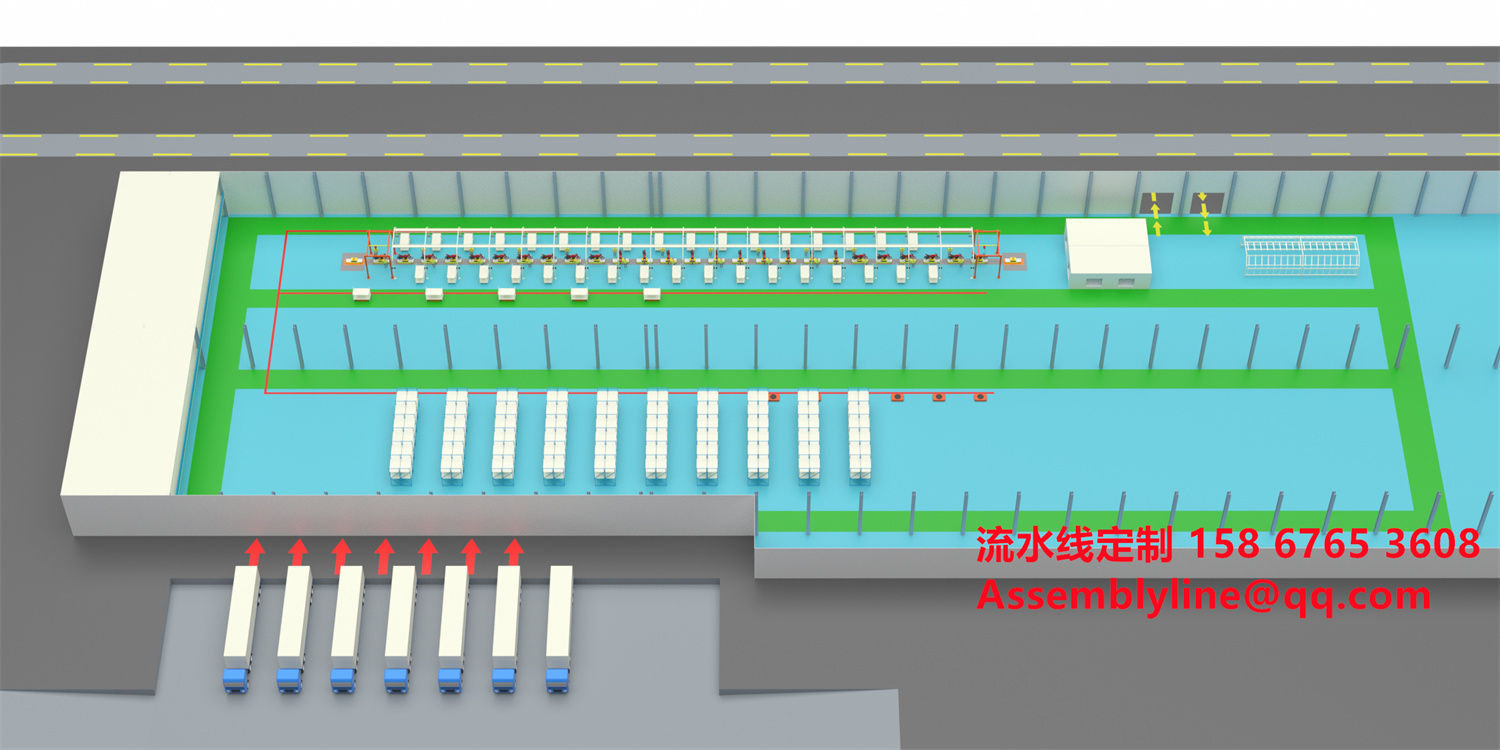

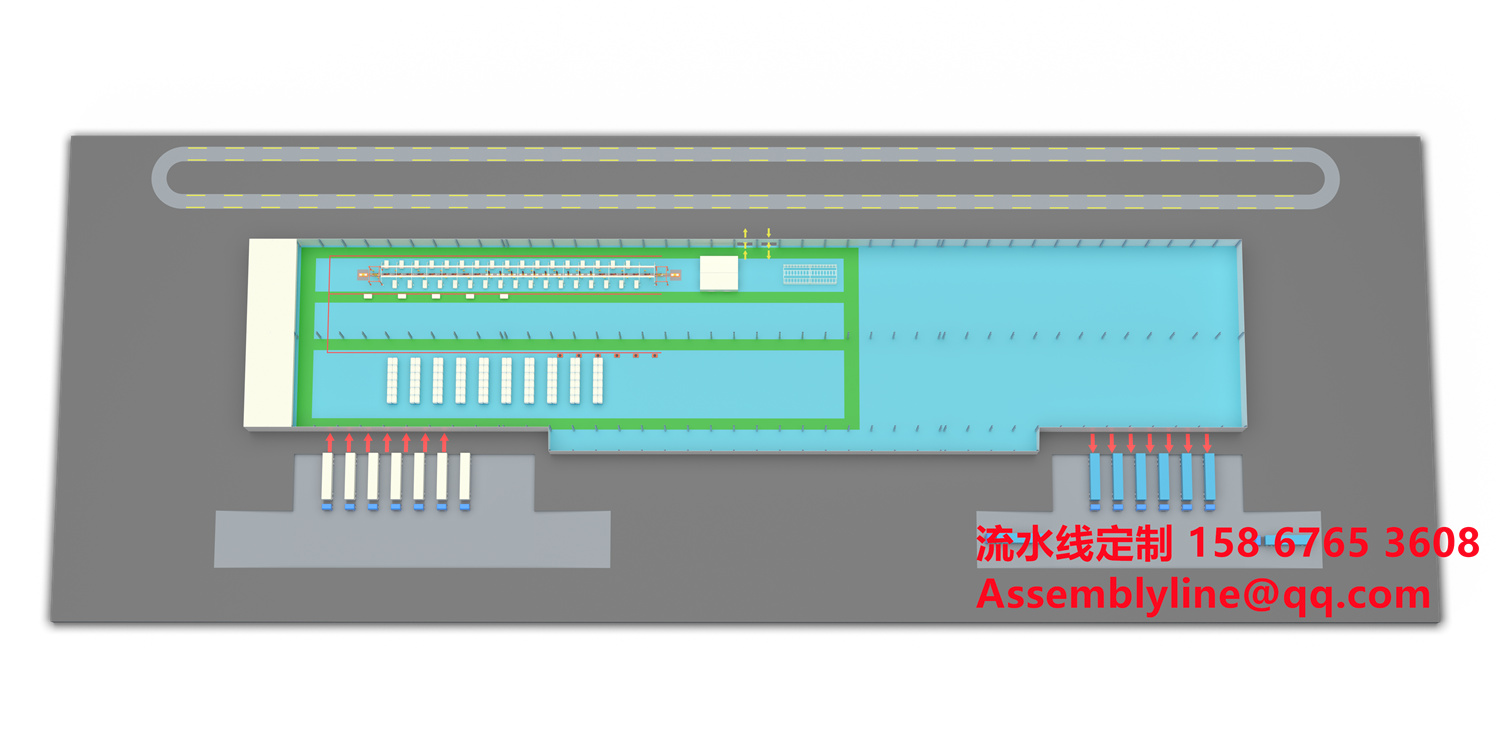

3.Space Utilization: Plan the workshop space rationally to ensure effective use of various functional areas such as assembly lines, material storage areas, and quality inspection areas.

4.Ergonomics: Consider ergonomic principles to ensure that workstations are designed in accordance with ergonomics, reducing worker fatigue and improving work efficiency.

5.Safety Considerations: When designing the layout, consider the setting of safety passages, emergency exits, and safety facilities to ensure worker safety.

6.Material Flow: Design an efficient material flow to reduce stagnation and waiting during material handling, improving material turnover efficiency.

7.Quality Control Areas: Set up quality control areas at key points on the production line for timely detection and resolution of issues.

8.Maintenance and Repair Areas: Establish dedicated maintenance and repair areas for quick response to equipment failures and necessary maintenance.

9.Environmental Control: Control the workshop environment, including temperature and humidity control, lighting, and noise management, to create a suitable working environment.

10.Scalability: Consider the possibility of future expansion, reserving space and interfaces to adapt to the growth of production scale and technological upgrades.

By applying these layout knowledge points, the motorcycle assembly production line can achieve production goals of high efficiency, high quality, and high safety.

The assembly production line of renowned motorcycle manufacturers is characterized by high levels of automation with robots and machines executing repetitive and precision tasks. Modular design allows for swift adjustments to accommodate various motorcycle models. Lean manufacturing principles are implemented to streamline processes and eliminate waste, enhancing efficiency. Rigorous quality control checkpoints ensure adherence to quality standards. Efficient material management and inventory control systems guarantee timely and accurate supply of production materials. The production capacity is flexible, adjusting quickly to market demands. Regular staff training enhances skills and adaptability to the production line. Environmental protection is emphasized with eco-friendly materials and energy-saving technologies. As technology advances, there is continuous exploration into new realms of intelligent and automated assembly, especially for electric motorcycles. A commitment to ongoing innovation keeps these manufacturers at the forefront of the industry, adapting to new technologies to improve production capabilities and product quality.

A well-planned workshop layout offers significant advantages for motorcycle production. It enhances efficiency by ensuring smooth assembly processes and reducing material handling time, thereby lowering production costs. Effective space planning allows for the optimal use of various functional areas such as assembly lines, quality inspection zones, and storage areas, while streamlining material flow to minimize production delays. The application of ergonomics improves worker comfort and efficiency, reducing the risk of occupational injuries. The strategic placement of safety passages and emergency exits ensures worker safety. Additionally, environmental controls such as temperature, humidity, lighting, and noise management provide a healthy and comfortable working environment that helps maintain production efficiency and product quality. Ultimately, a well-thought-out layout should also consider future scalability and technological upgrades to ensure the long-term competitiveness of the production line.

Factory address: East Industrial Cluster, Wenling City, Zhejiang Province

Aircraft: Taizhou Luqiao Airport (1 hour) Wenzhou Airport (2 hours)

High speed rail: Wenling Station (40 minutes)

Expressway intersection: Wenling North (15 minutes) Wenling East (20 minutes)

Contact our engineering team and get company info

Email: Assemblyline@qq.com