Photovoltaic (PV) modules, also known as solar photovoltaic panels or solar panels, are the core components of solar power generation systems, responsible for converting solar energy into electrical energy. Here is a detailed introduction to the types, structure, characteristics, automated assembly production process, and production line equipment of photovoltaic modules:

Types of Photovoltaic Modules

- Monocrystalline Solar Cells: High photovoltaic conversion efficiency, ranging from 17% to 24%, but relatively high cost. Typically encapsulated with tempered glass and waterproof resin, offering a quality guarantee of up to 25 years.

- Polycrystalline Solar Cells: Slightly lower conversion efficiency than monocrystalline, but lower cost and commonly found in the market.

- Thin-film Solar Cells: Including amorphous silicon thin-film solar cells, characterized by flexibility and lightweight, suitable for special application scenarios.

Structure of Photovoltaic Modules

- Glass: Usually ultra-white textured tempered glass with high light transmittance and UV resistance.

- EVA (Ethylene-Vinyl Acetate): Acts as a sealing agent and connector, with high light transmittance and anti-aging capabilities.

- TPT (Thermoplastic Polyolefin): Used as the backsheet material, characterized by aging resistance, corrosion resistance, etc.

- Solar Cells: The power generation main body, which can be monocrystalline or polycrystalline solar cells.

- Backsheet: Protects the solar cells and provides mechanical support.

- Junction Box: Connects the internal output circuit of the solar cell module with the external circuit.

Characteristics of Photovoltaic Modules

- Good structural stability, capable of withstanding harsh environmental conditions.

- High efficiency, especially for high-efficiency crystalline silicon PV modules such as HJT, TOPCon, IBC, etc.

- Wide application, suitable for various scales of photovoltaic power generation systems.

- Flexibility and lightweight, especially for thin-film PV modules.

Automated Assembly Production Process

- Cell Testing: Classify the cells based on their performance parameters to improve the utilization rate of the cells.

- Front Side Welding: Weld the busbar to the front main grid of the cell.

- Back Side Interconnection: Interconnect the cells to form a module string.

- Laying: Lay the module string, glass, EVA, solar cells, and backsheet in a certain order.

- Module Laminating: Laminate the components by vacuuming and heating to melt the EVA, bonding the cells, glass, and backsheet.

- Edge Trimming: Trim the edges where the EVA has extended outward after lamination.

- Frame Assembly: Add an aluminum frame to the glass module to increase the strength and sealing of the module.

- High Voltage Testing: Test the module's voltage resistance and insulation strength.

- Module Testing: Calibrate the output power of the cells to determine the quality grade of the module.

Production Line Equipment

- Laser Cutting Machine: Used for precise cutting of solar cells.

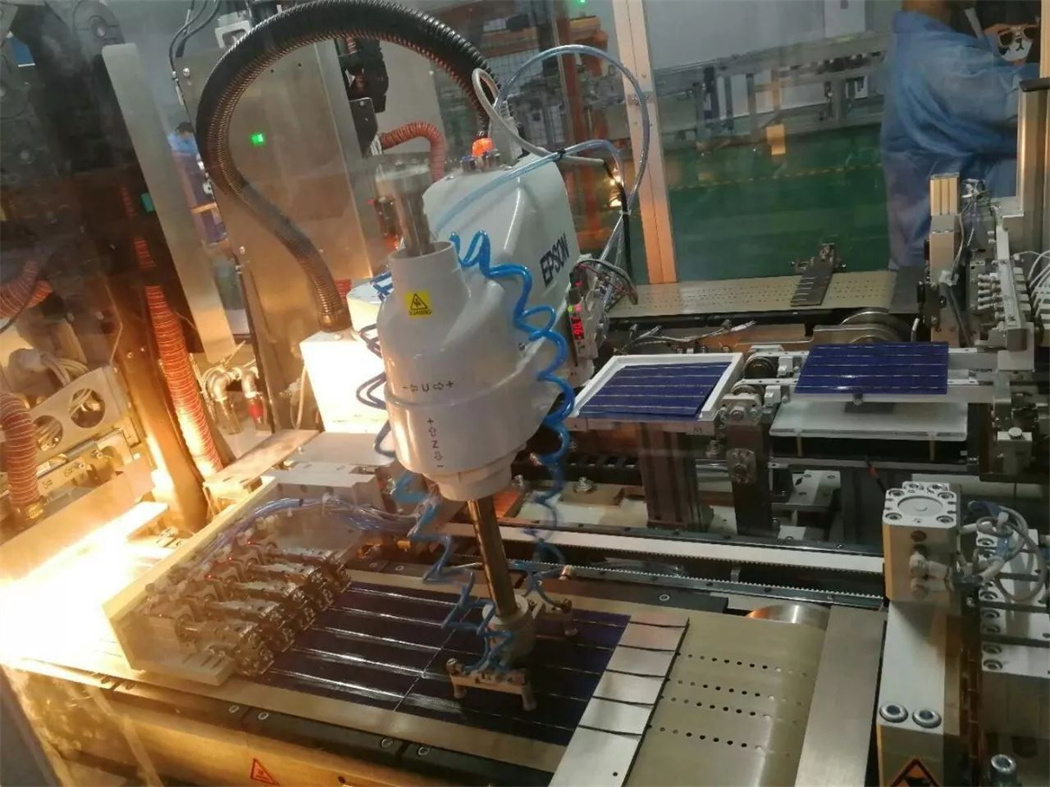

- Stringing Machine: Used for interconnecting solar cells.

- Automatic Lamination Equipment: Used for automatically laminating solar cells and EVA materials.

- Laminator: Used for the lamination and curing of modules.

- Automatic Assembly Line: Used for the automated transmission and control of the entire production process.

- Automatic Barcode Device: Achieves automatic printing, cutting, placement, and data tracing of barcodes.

With technological advancements, the automated production of photovoltaic modules continues to be optimized, improving production efficiency and product quality, while also reducing production costs.

The photovoltaic panel production line is a highly automated manufacturing process that involves precise testing, classification, welding, and interconnection of solar cells, as well as the automatic lamination and pressing using materials such as EVA encapsulant and TPT backsheet. Key equipment on the production line includes laser cutting machines, stringing machines, automatic lamination equipment, laminators, and automatic assembly lines, all working in concert to ensure the quality and consistency of the modules. Additionally, an automated barcode system is used for product traceability and quality control. The entire production process is carried out with high efficiency and output through precision machinery and intelligent control systems, meeting the growing global demand for clean energy solutions.

Solar Photovoltaic Panel Production Line

Factory address: East Industrial Cluster, Wenling City, Zhejiang Province

Aircraft: Taizhou Luqiao Airport (1 hour) Wenzhou Airport (2 hours)

High speed rail: Wenling Station (40 minutes)

Expressway intersection: Wenling North (15 minutes) Wenling East (20 minutes)

Contact our engineering team and get company info

Email: Assemblyline@qq.com