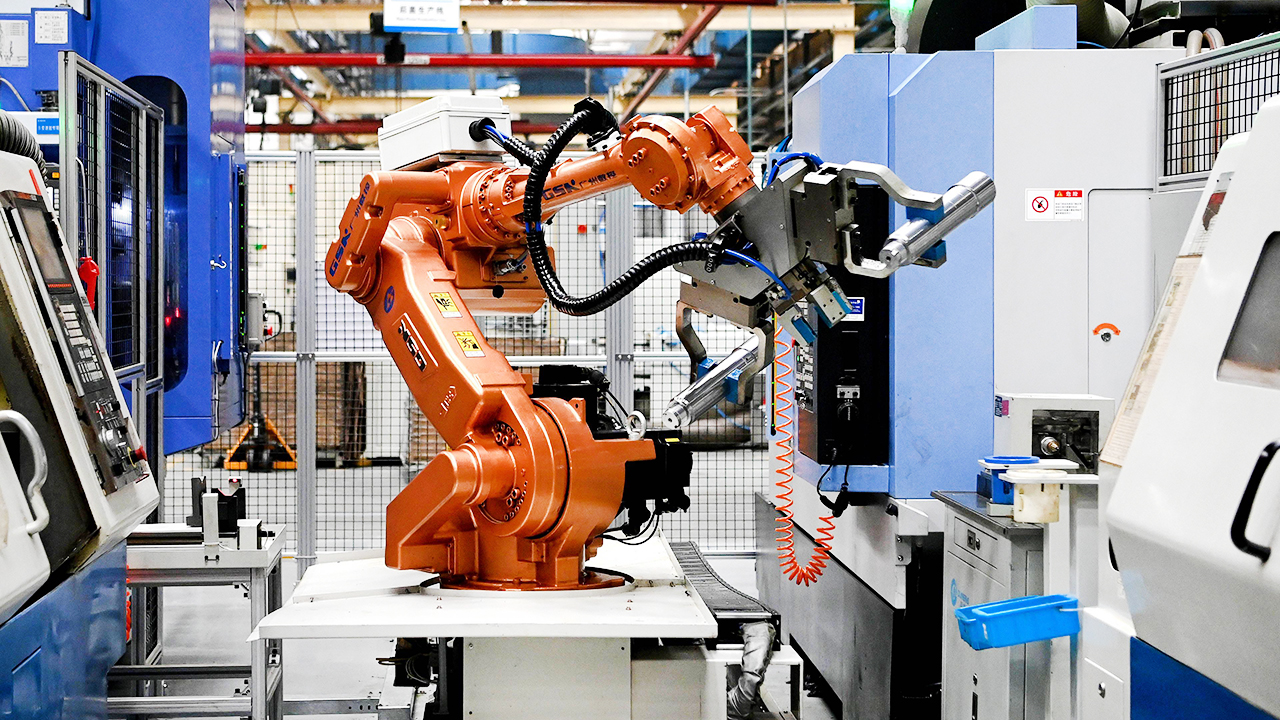

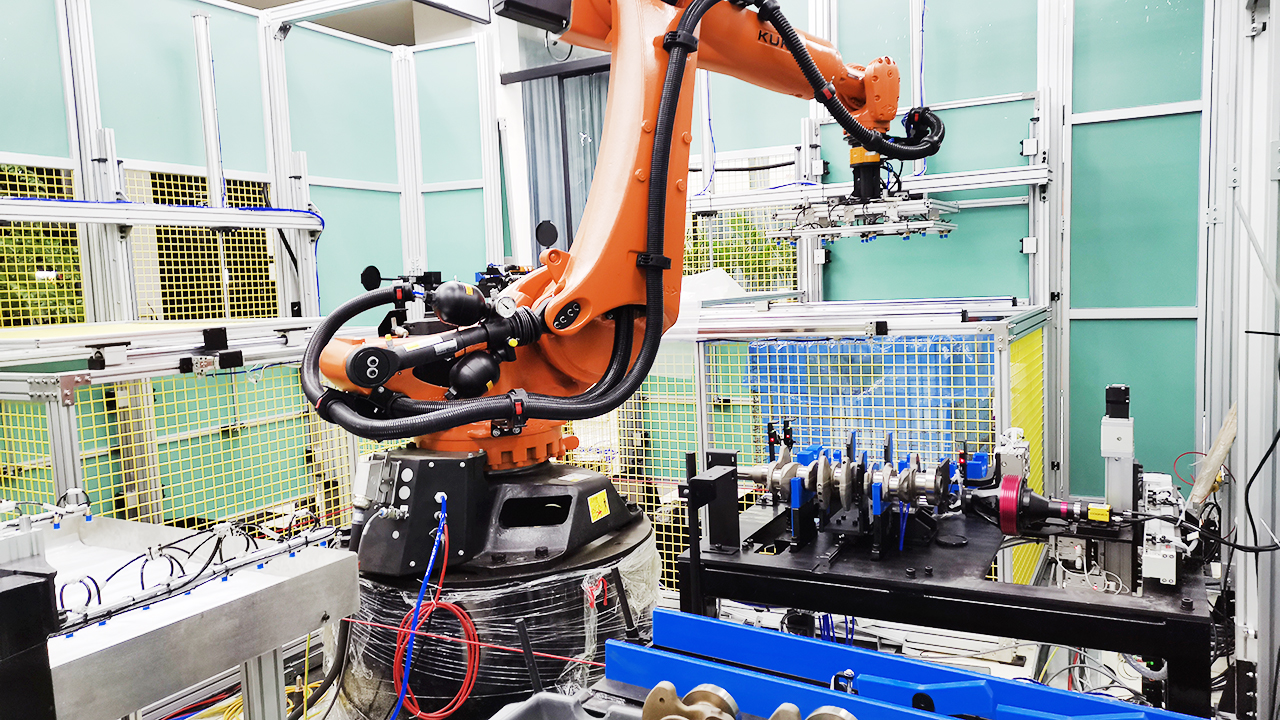

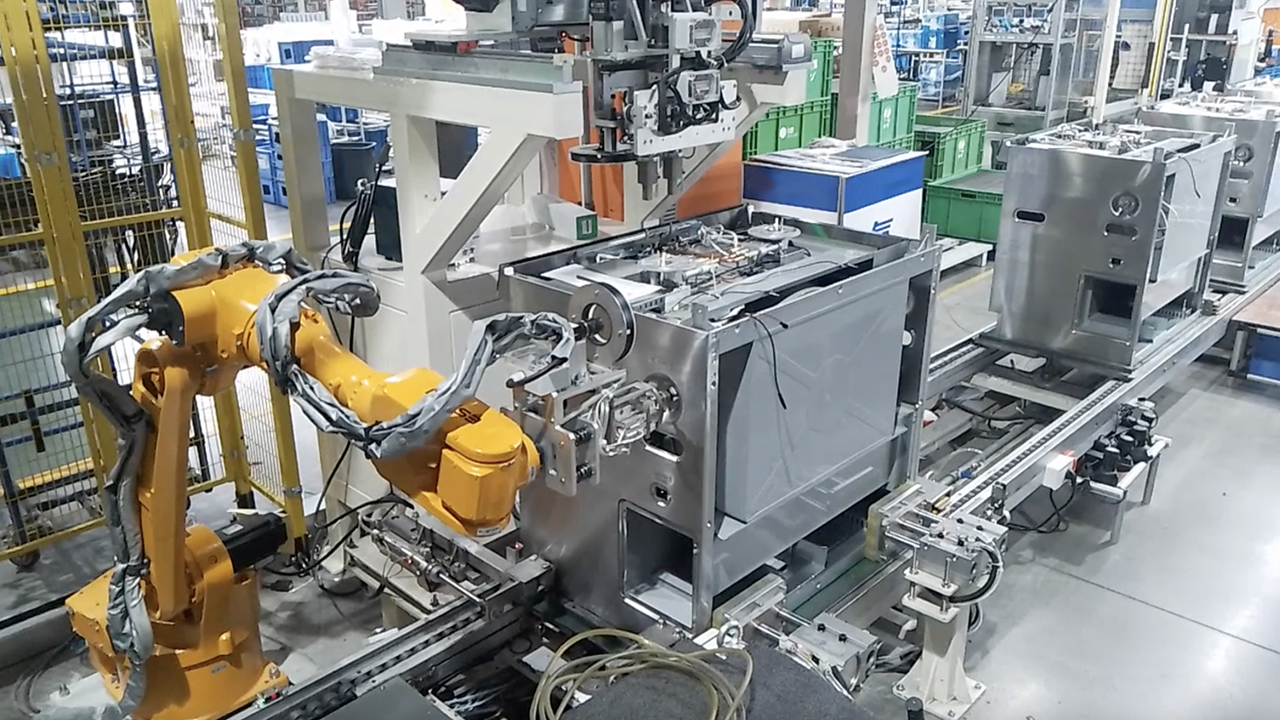

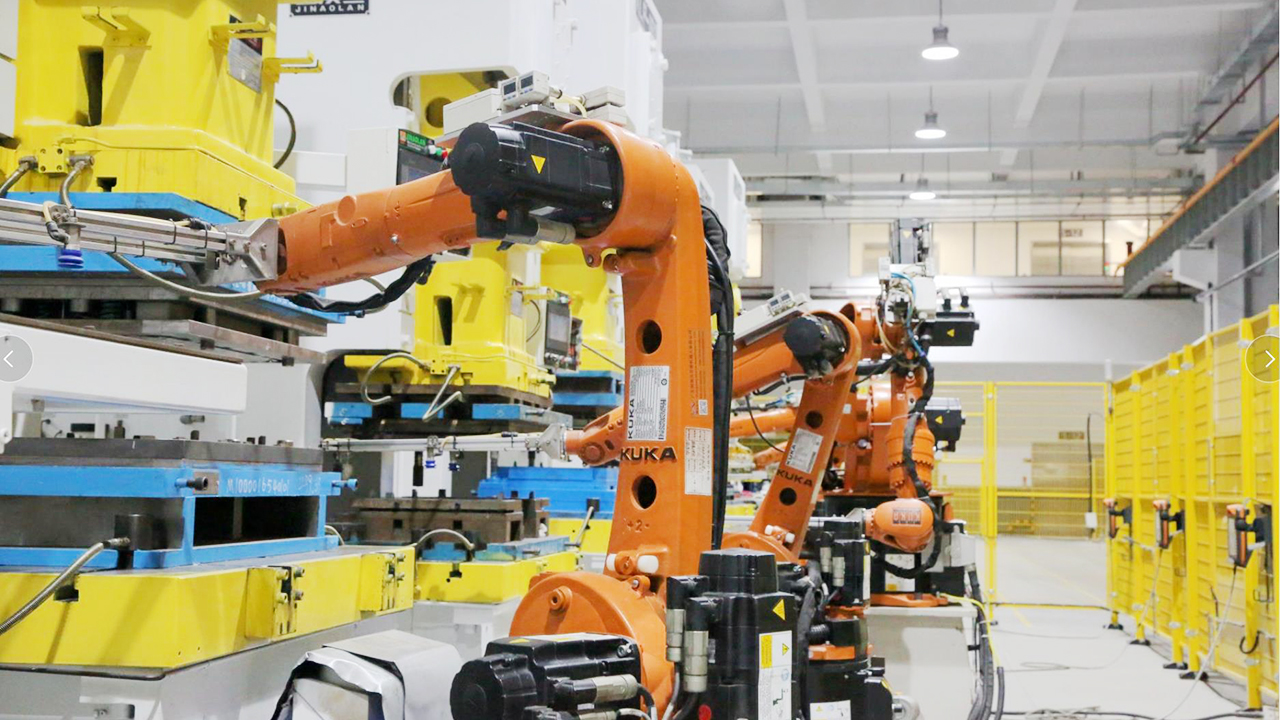

Robots used in production and assembly lines come in a variety of types, each with unique characteristics and applications:

- Material Handling Robots: Used for moving raw materials or finished products, typically with high load capacity and precise positioning systems.

- Welding Robots: Specialized for welding tasks, offering high precision and repeatability for complex welding operations.

- Painting Robots: Designed for applying paint or coatings to products, providing an even finish.

- Assembly Robots: Used for assembling product components with flexibility and precision to meet various assembly requirements.

- Packing Robots: Automate the packaging process, including boxing, sealing, and labeling.

- Inspection Robots: Used for quality inspection of products, capable of identifying defects and sorting.

- Palletizing Robots: Used to neatly stack products on pallets, improving warehouse storage efficiency.

- Cutting Robots: Used for cutting materials such as metal sheets or plastics, characterized by high precision and efficiency.

- Polishing Robots: Used for polishing product surfaces to enhance the quality of the product's appearance.

- Flexible Manufacturing Systems (FMS): Integrate various robots and automated equipment to flexibly handle different production tasks.

The characteristics of each type of robot include but are not limited to:

- Precision: Capable of performing operations with millimeter-level accuracy.

- Speed: Quickly completing tasks to increase production efficiency.

- Repeatability: Able to repeat the same task without error.

- Flexibility: Adaptable to different production needs and environments.

- Reliability: Stable operation over long periods, reducing the rate of malfunctions.

- Ease of Programming: Users can program robots to perform specific tasks as needed.

- Safety: Reduces manual operation, lowering the risk of workplace accidents.

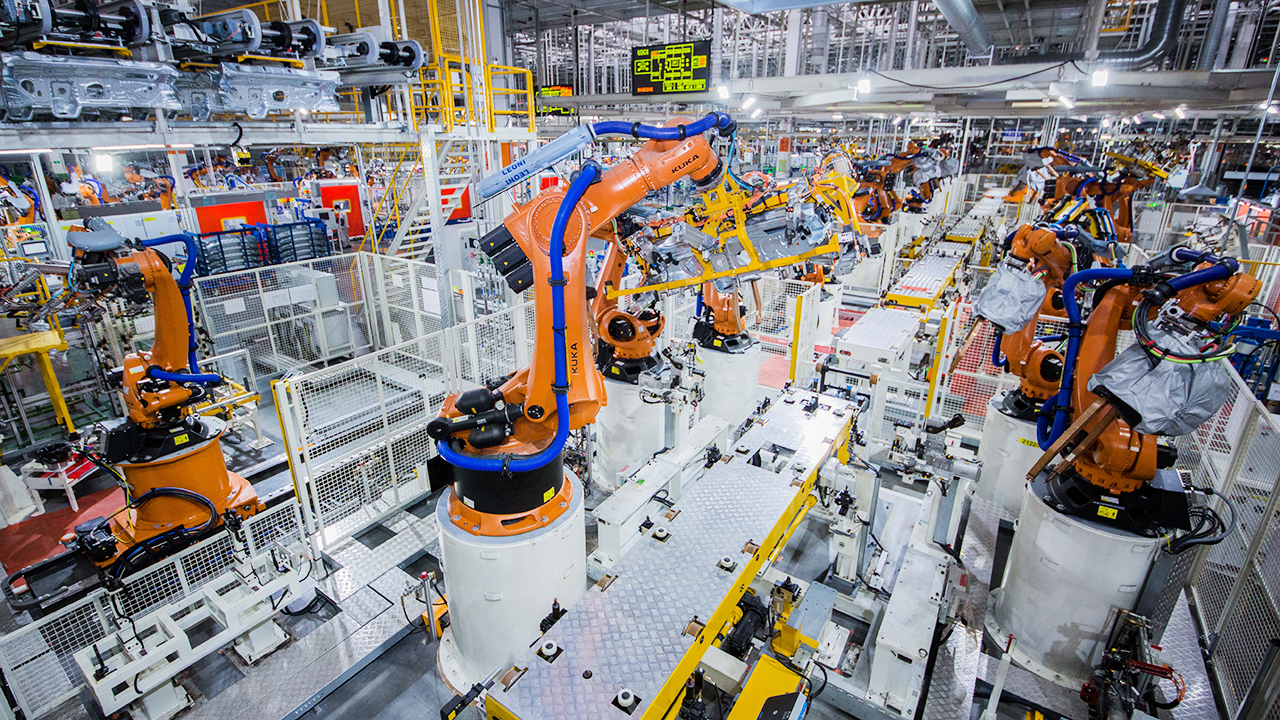

With technological advancements, these robots are becoming more intelligent, capable of self-optimization and adapting to more complex tasks through machine learning and artificial intelligence technologies.

The benefits of using robots in assembly and production lines include:

- Increased Efficiency: Robots can work continuously around the clock without rest, significantly improving production efficiency.

- Reduced Errors: The precision and consistency with which robots perform tasks reduce human errors.

- Lowered Costs: In the long run, robots can reduce labor and training costs.

- Improved Safety: Robots can perform dangerous or health-hazardous tasks, reducing the risk of worker injuries.

- Enhanced Product Quality: Robots maintain consistent process standards, improving product quality.

- Flexibility: Many robots can be reprogrammed to adapt to different production needs.

- Waste Reduction: Robots can use materials precisely, reducing waste.

- Easy Maintenance: Robots typically have longer maintenance cycles, reducing maintenance costs.

- Environmentally Friendly: Robot operations can reduce energy consumption and be more environmentally friendly.

- Innovation Promotion: Advances in robotics technology drive innovation and optimization of production processes.

- Competitiveness Enhancement: Using robots can improve production speed and quality, enhancing a company's market competitiveness.

- Adaptability: Robots can adapt to different working environments and conditions, including high-temperature, low-temperature, or dust-free environments.

- Data Collection: Robots can be integrated with sensors to collect data during the production process for further analysis and improvement.

- Scalability: As production demands grow, more robots can be added to expand the production line.

- Reduction of Human Factors: Robots are not affected by emotions, fatigue, or other human factors and can perform tasks stably.

Using robots can bring many long-term benefits to businesses, especially in terms of improving production efficiency and quality.

Assembly lines and industrial robots are the cornerstones of modern manufacturing. These highly automated systems significantly enhance production efficiency and product quality through precise, repetitive task execution. Industrial robots can undertake dangerous or repetitive labor, reduce human errors, and lower production costs. The flexibility and programmability of assembly line robots allow them to adapt to changing production demands, while advanced sensors and control systems ensure the precision and consistency of operations. With technological advancements, these robots are becoming more intelligent, capable of self-optimization and performing more complex tasks, further propelling the development of the manufacturing industry.

Assembly Line Robots Industrial robot types

Factory address: East Industrial Cluster, Wenling City, Zhejiang Province

Aircraft: Taizhou Luqiao Airport (1 hour) Wenzhou Airport (2 hours)

High speed rail: Wenling Station (40 minutes)

Expressway intersection: Wenling North (15 minutes) Wenling East (20 minutes)

Contact our engineering team and get company info

Email: Assemblyline@qq.com