Pickup trucks are versatile light-duty trucks with complex structures and assembly production processes that involve multiple steps and techniques. Here's an introduction to the structure of pickup trucks, assembly production processes, automated assembly lines, and MES systems:

Structure of Pickup Trucks

Pickup trucks typically have the following structural features:

Body-on-Frame Design: Pickups often use a body-on-frame design with a separate chassis and undercarriage.

Cargo Box: An open cargo box at the rear of the pickup for loading goods.

Cabin: A separate cabin for passengers, distinct from the cargo box.

Powertrain: Includes the engine, transmission, etc., to provide power output.

Assembly Production Process

The assembly production process for pickup trucks generally includes the following main steps:

Stamping: Steel sheets are cut and stamped into various components required for the vehicle body.

Welding: Automated welding techniques are used to assemble the stamped parts into a complete vehicle structure.

Painting: After rust prevention treatment by electrocoating, the body is painted.

Final Assembly: This includes the assembly of interiors, chassis, exteriors, and the final vehicle performance testing.

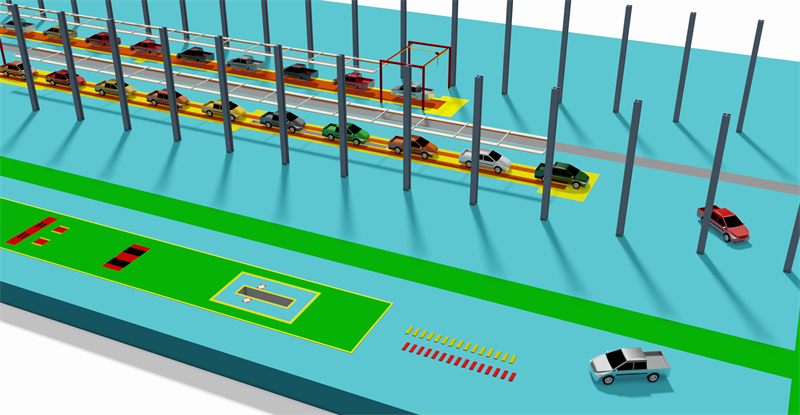

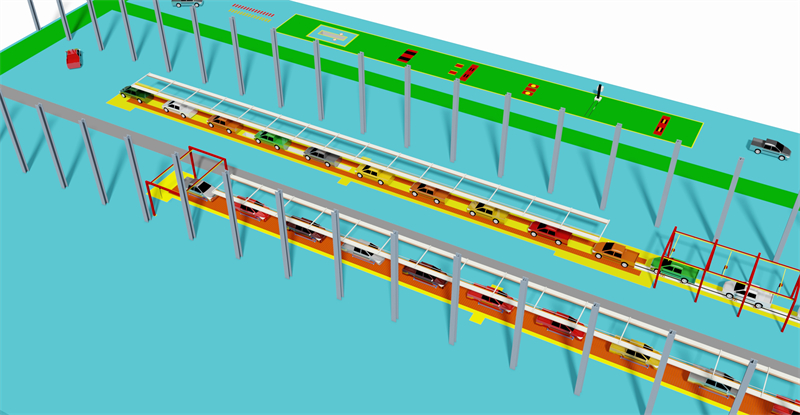

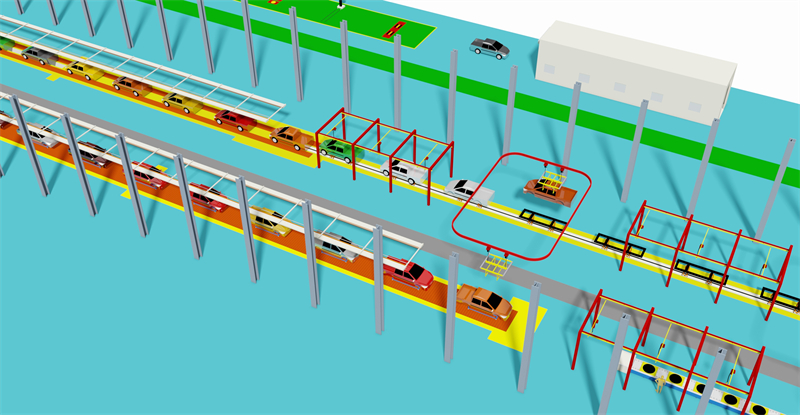

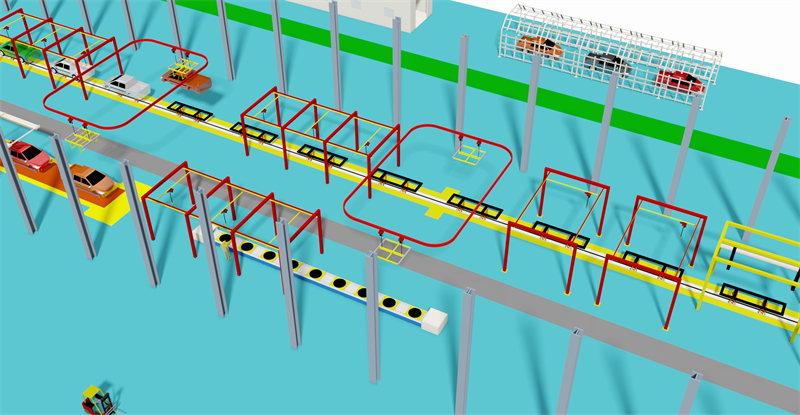

Automated Assembly Line

Automated assembly lines play a crucial role in the production of pickup trucks and include:

Robotic Welding: Automated welding robots enhance welding efficiency and quality.

Automated Conveyance Systems: Used for the transportation of parts and vehicle bodies to ensure smooth production processes.

Automated Assembly Equipment: Used for the automated assembly of interiors, chassis, and other components.

MES System

MES (Manufacturing Execution System) is vital in the production of pickup trucks, with functions including:

Production Scheduling: Establishing a unified command center to quickly respond to production changes.

Quality Management: Establishing a preventive quality control system to ensure product quality.

Equipment Management: Monitoring the operational status of equipment and implementing maintenance and repair.

Tracking and Tracing: Tracking the location and status of each project throughout the production process.

Process Management: Managing the production process from order to finished goods.

Resource Allocation and Status: Managing the allocation and status of resources, including equipment, materials, and workers.

Performance Analysis: Defining and tracking Key Performance Indicators (KPIs).

System Integration: Close integration with ERP, SCM, and other systems for data synchronization.

The MES system helps production managers make better decisions by collecting and analyzing real-time data, optimizing production operations, and improving efficiency and product quality.

Pickup truck assembly lines are highly efficient production lines specifically designed for manufacturing pickup trucks, featuring the use of high-strength steel for durable bodies; compatibility with various powertrains including diesel, gasoline, and hybrid systems; modular design for flexibility in producing different models; integration of automated robots and precision machining equipment; strict quality control processes; focus on environmental protection and energy efficiency, meeting emission standards; and multifunctionality of the produced pickups to cater to commercial, domestic, and off-road needs. These assembly lines offer a diverse range of high-performance pickup truck models to the market through their efficient and adaptable production capabilities.

Pickup Truck Assembly line CKD SKD

Factory address: East Industrial Cluster, Wenling City, Zhejiang Province

Aircraft: Taizhou Luqiao Airport (1 hour) Wenzhou Airport (2 hours)

High speed rail: Wenling Station (40 minutes)

Expressway intersection: Wenling North (15 minutes) Wenling East (20 minutes)

Contact our engineering team and get company info

Email: Assemblyline@qq.com