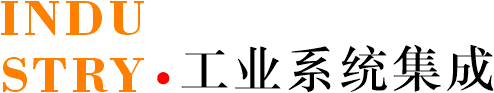

Processing and handling robots on assembly lines

Assembly and handling robots on production lines have a wide range of applications, with various types and features as follows:

-

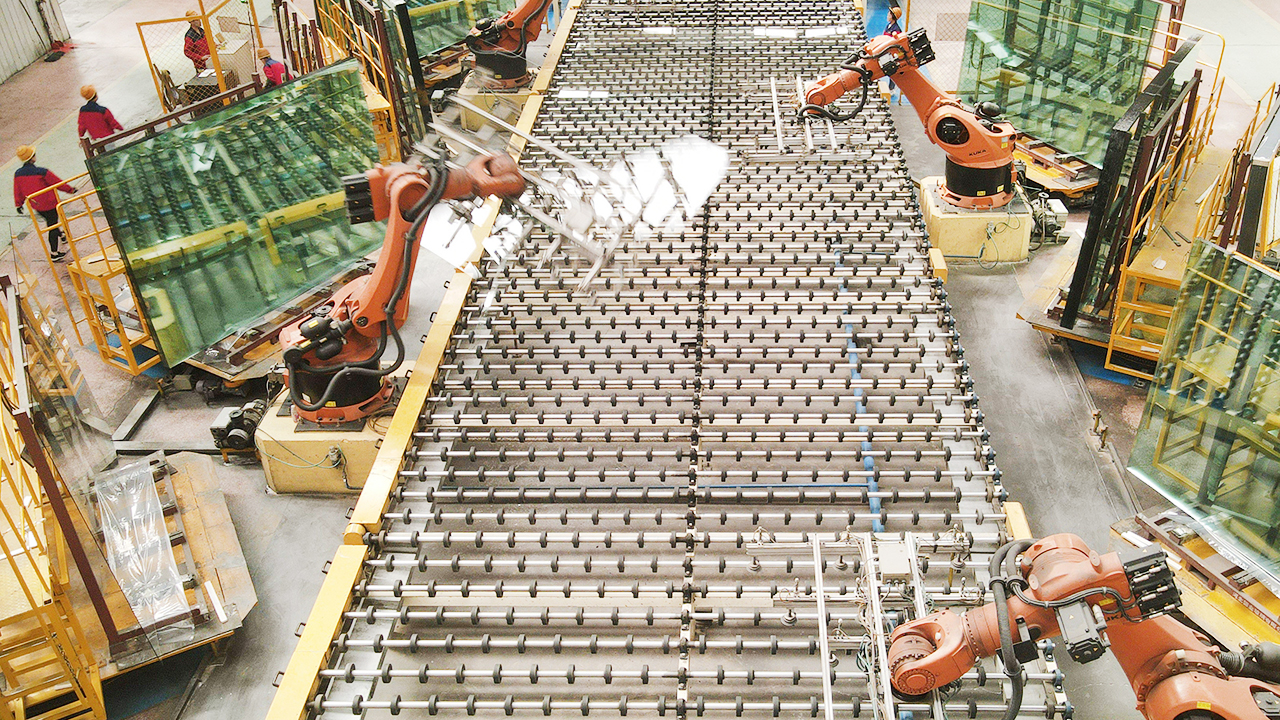

Assembly Robots:

- Used for assembling products on the production line, capable of handling delicate part assembly, commonly found in the electronics manufacturing industry.

-

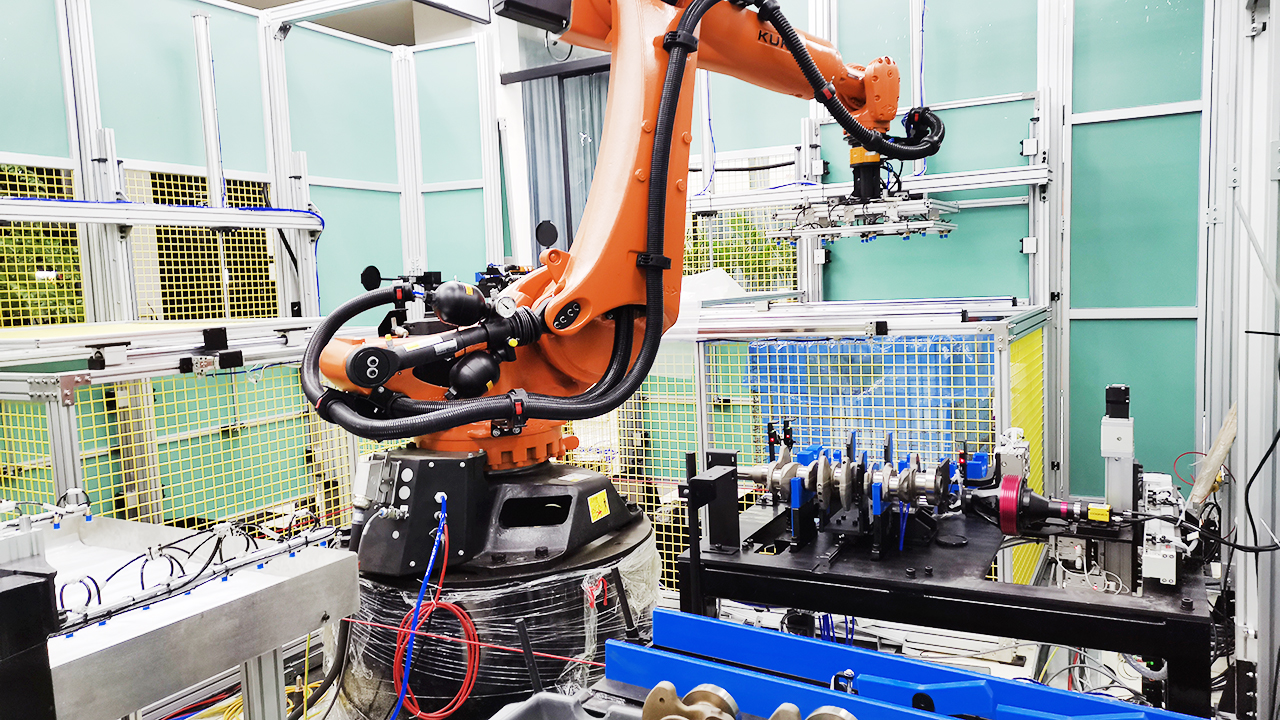

Handling Robots:

- Responsible for moving products or semi-finished goods from one station to another on the production line, or from the production line to the storage area.

-

Palletizing Robots:

- Specifically designed to stack products neatly for subsequent transportation and storage, widely used in industries such as food, chemicals, and beverages.

-

Automated Guided Vehicles (AGVs):

- Capable of autonomous movement within the factory, commonly used for the transportation and handling of materials, navigated by lasers, magnetic strips, or vision systems.

-

Sorting Robots:

- Utilize sensors and image recognition technology to automatically identify and sort different products, suitable for logistics centers and product categorization.

-

Roller Conveyor Robots:

- Suitable for use in automated production lines to improve the efficiency and accuracy of material handling, commonly used in packaging and sorting processes.

-

Vision Navigation Systems:

- Combine cameras and sensors to obtain environmental information for navigation, suitable for complex or variable handling tasks.

Features of production line robots include:

- High Efficiency: Robots can work continuously at high speed, significantly increasing production efficiency.

- Precision: Robots are precisely positioned, reducing human errors.

- Flexibility: Many robots are designed to be programmable and have multiple degrees of freedom, capable of adapting to different production line requirements.

- Reliability: Compared to manual operations, robots have higher repeatability and reliability.

- Safety: Robots can operate stably in hazardous or environments where humans cannot work for long periods.

- Cost-effectiveness: Although the initial investment is relatively high, it can save on labor costs in the long run.

With technological advancements, the intelligentization, flexibility, and collaboration of production line robots will be the future development direction.

Processing and handling robots on assembly lines, including assembly, handling, palletizing, and sorting types, are characterized by high efficiency, precision, flexibility, reliability, safety, and cost-effectiveness. They enhance the efficiency and quality of production processes through intelligence and automation.