The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line:

Cell Types

Cells are the basic units that make up the battery pack, mainly divided into:

PACK Structure and Processes

The PACK is composed of multiple cells connected in series and parallel, including:

Production processes cover cell selection and grouping, welding, assembly, aging testing, inspection, and packaging.

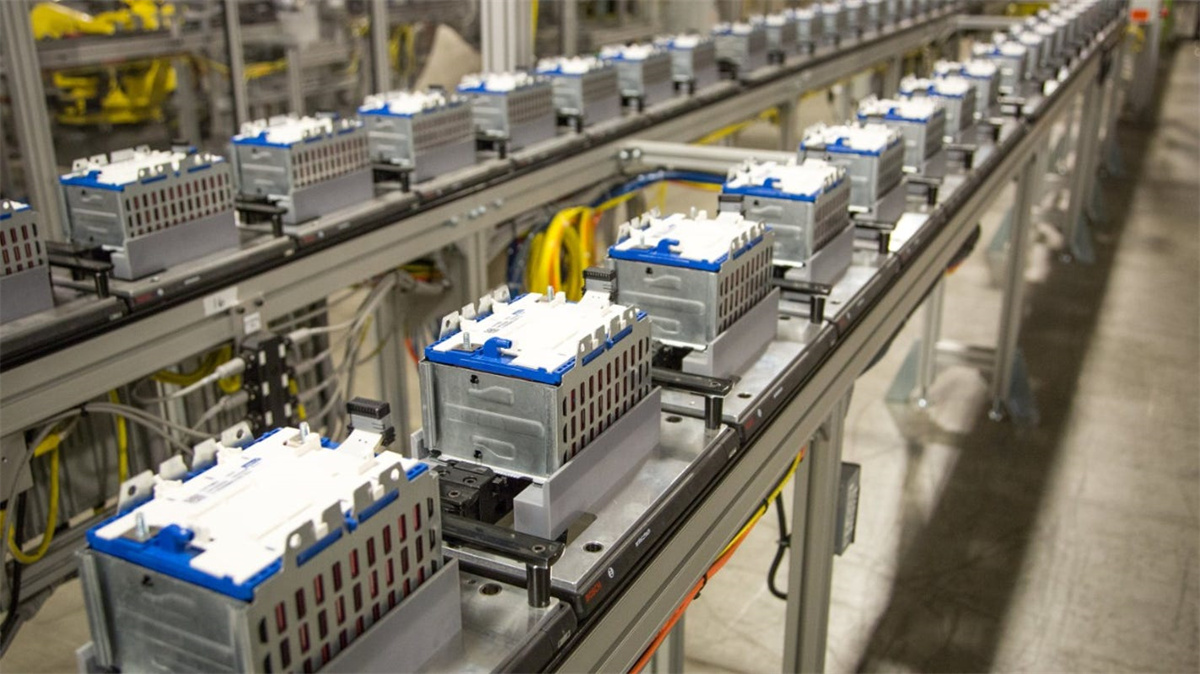

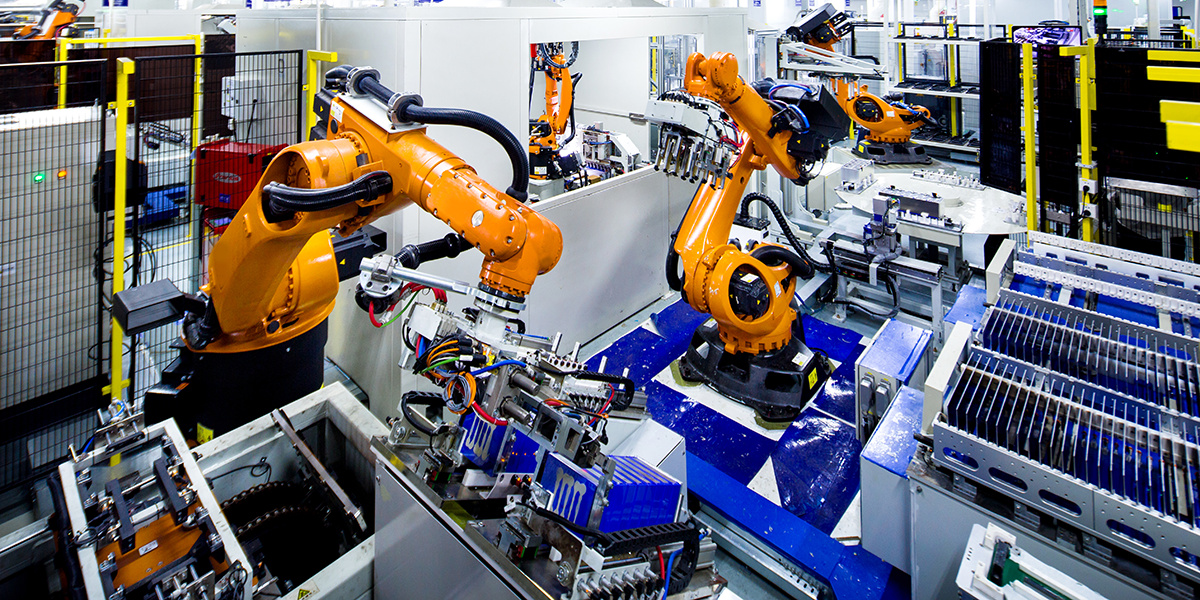

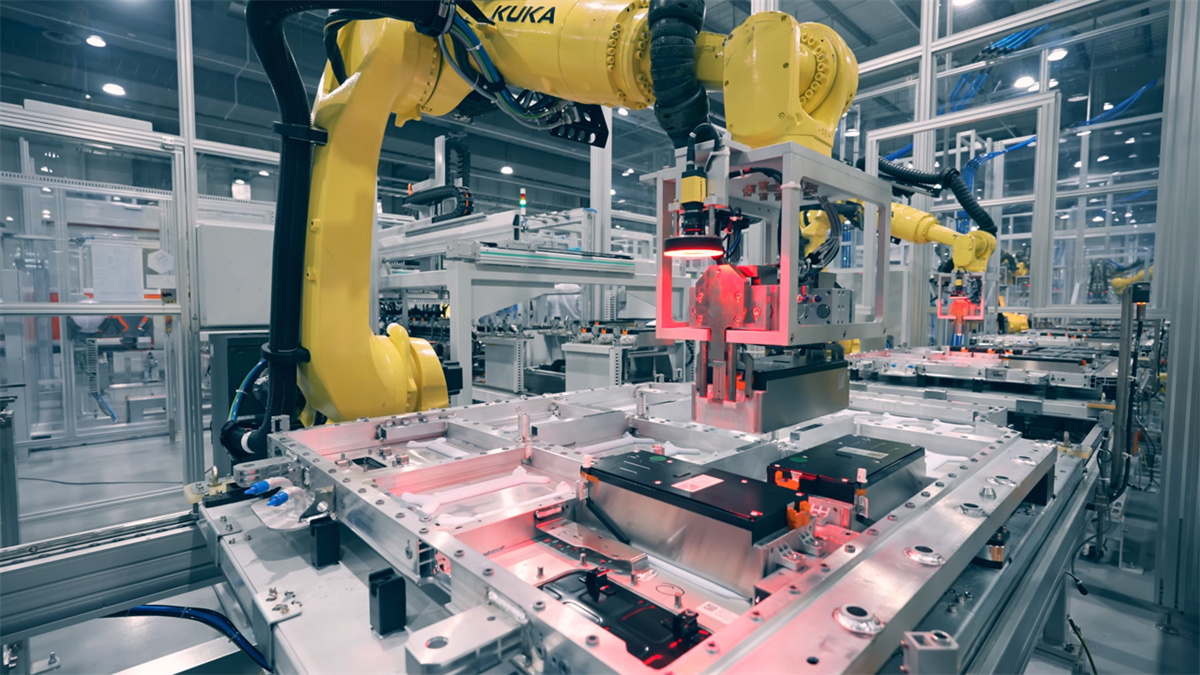

Assembly Production Line

The process flow of the PACK production line includes:

Testing Equipment

Testing equipment used in the PACK line includes:

These devices ensure that the lithium battery PACK meets performance and safety standards.

Lithium Battery PACK Production Line Processes and Equipment

Factory address: East Industrial Cluster, Wenling City, Zhejiang Province

Aircraft: Taizhou Luqiao Airport (1 hour) Wenzhou Airport (2 hours)

High speed rail: Wenling Station (40 minutes)

Expressway intersection: Wenling North (15 minutes) Wenling East (20 minutes)

Contact our engineering team and get company info

Email: Assemblyline@qq.com